Keeping Up with Technology

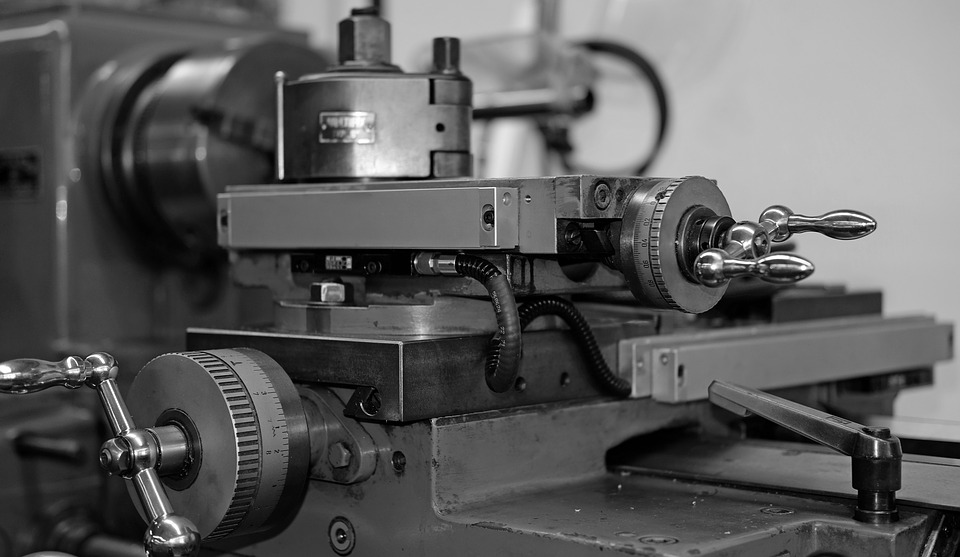

The machining industry is no stranger to adaptation and change. Over the past few decades alone newer more efficient methods and equipment have been incorporated into the industry. Those who could not or refused to adapt didn’t make it. Demand has always affected supply, meaning suppliers will always strive to satisfy all their customers needs. Naturally, more demand equals more production needs. In today’s industry manufacturers will need more efficiency without losing accuracy.

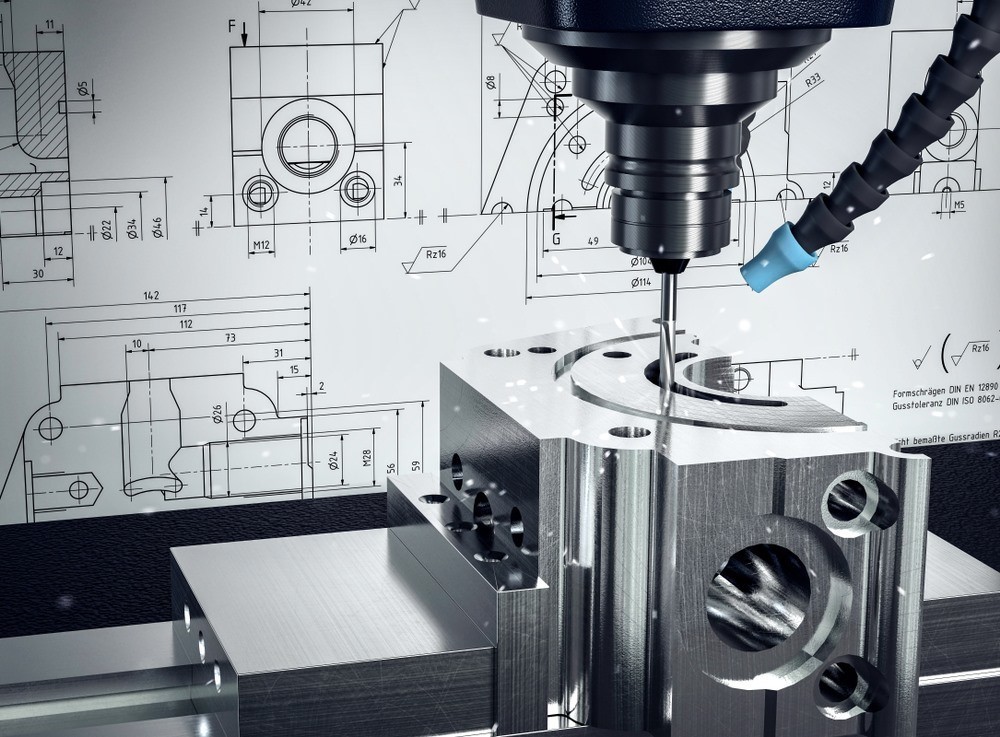

That’s where technology comes in to play. As consumer demand continues to climb and prices fall, due to heavy manufacturing competition, the machining industry is being forced to change and adapt once again. Luckily, CNC machine services have also become more affordable and easier to transition into the machining industry over the past few years. CNC stands for computer numerical control and it allows for pre-programmed software to direct movements of machines and tools. This new technology together with CAD, a computer aided design software, can be used in precision machine shops to improve productivity. For both low and high volume machining shops.

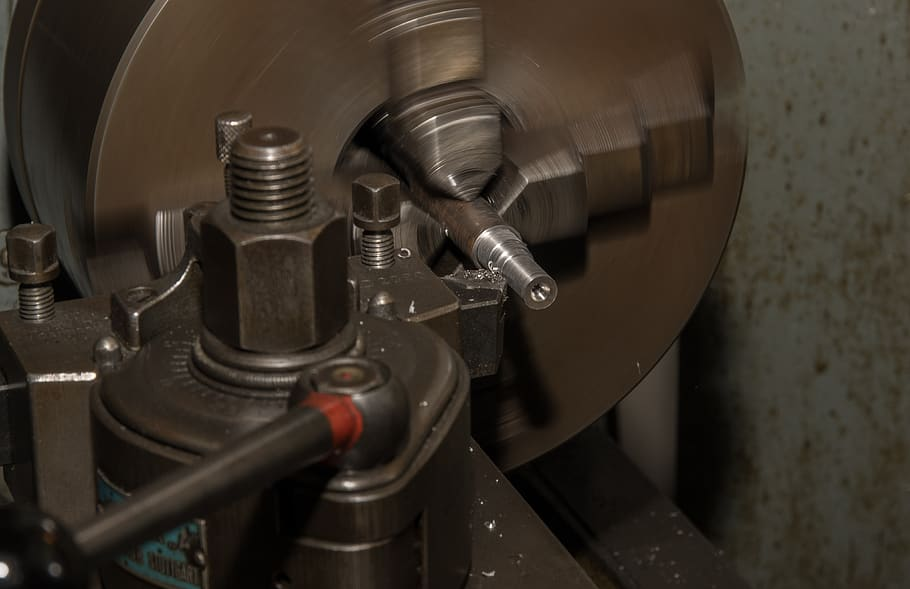

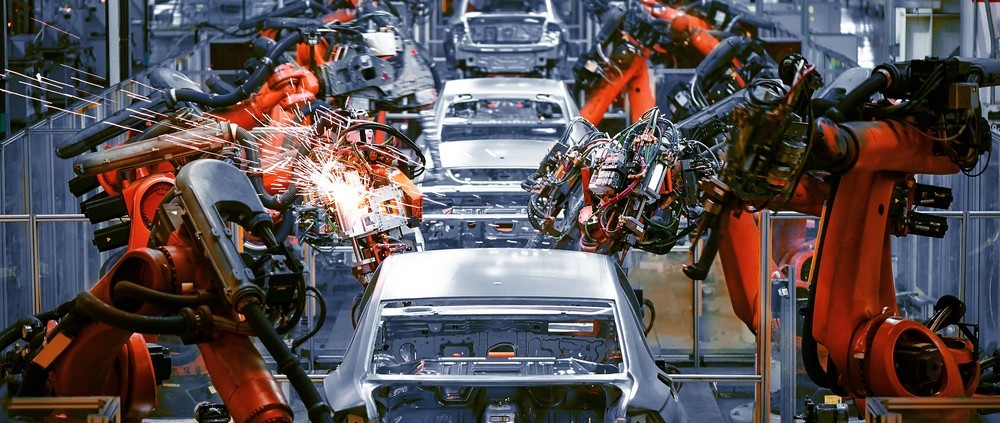

Robotics and machine automation have long been a part of the machining industry but not to this extent. People have been the main workforce in the industry, but old methods and equipment aren’t proving sufficient to keep up with the growing consumer demand. Lower pricing, although great for the customer, is hurting the industry. Companies are finding it even harder to hire quality employees, let alone pay them fair wages. Technology being the route of the cause as well as being the solution.

Advanced Affordable Equipment Helps Easy Integration

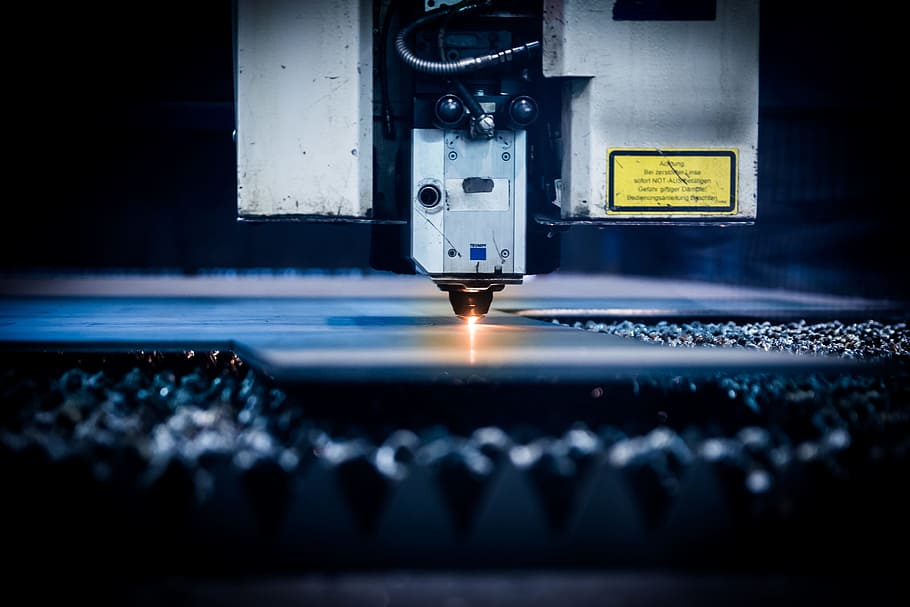

3D printing is becoming the next big thing. Big data is helping increase productivity tremendously and those who can’t get on board will surely not be able to compete. We all know integration is not easy, especially when it’s at such large a scale and new technology is never cheap. Well, time does not agree. Just like all other advancements in technology, more demand means more production. This leads to more competition resulting in lower prices for updated equipment. With price no longer being a concern the transition from a regular machine shop to a CNC machine shop becomes a bit easier.

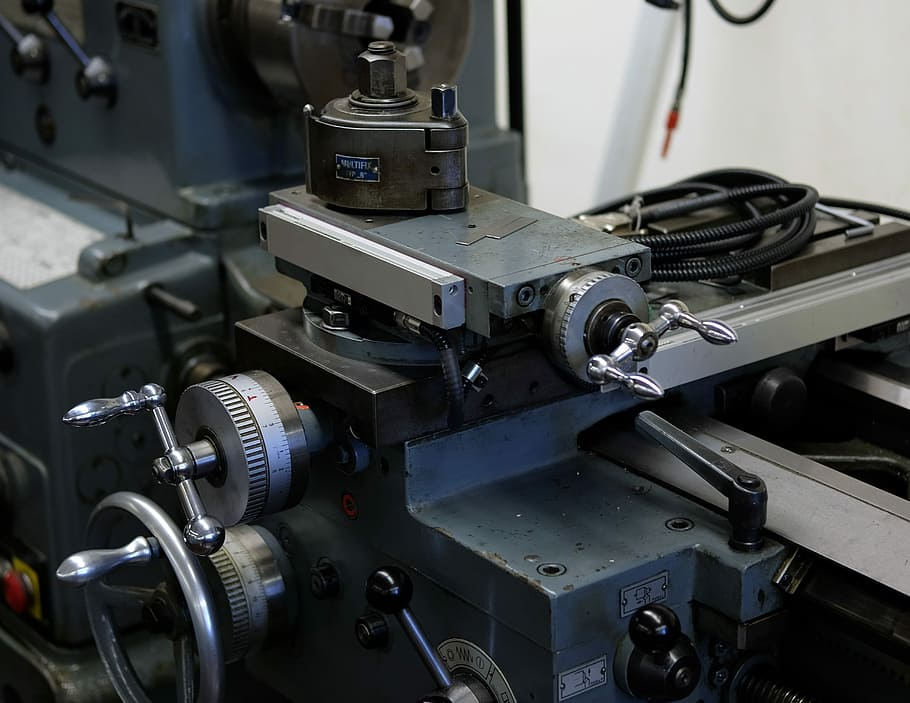

Now add on advanced aiding software such as CAD or CAM and it gets even easier. CAD together with CNC machine services or CNC turning services can help with assembly and maintain production. CAD can design, control, and train. It allows for the processing and receiving of data, in turn allowing the software to take immediate action. These new machines can basically adjust and think for themselves making everything easier, even high volume machining.

Tech Availability, Maintenance, and Repair Cost?

There is no denying that jobs are looking for computer savvy employees now more so than ever before. Most fields of work are slowly being taken over by technology just like the machining industry. Employers need people who can understand software to be able to run all this new smart equipment. People who are trained and certified to CNC or similar technology. We no longer think brawn when we think of the machining industry, companies want smarts above all now.

This allows for more opportunity in the tech and repair field. Computer skills are all but mandatory for job security now and people are taking advantage of it. Again, the demand for CNC turning services and for CNC machining services technicians has risen which opens more jobs. More job availability means companies can hire the right person for the job at fair wages. This kind of worker used to be hard to come by or was too expensive to bring on board but not anymore.

Technology is taking over and people are aware of it. Taking full advantage of this new wave of opportunity in the workforce is a good thing for CNC machine shop employers.

So, Gear Up and Get Back On Top of the Game

For such factories as a, precision machine shop, robotics and automation systems are not strangers. The increased need for these machines and the fact that they continue to get smarter however does cause concern. The machining industry is changing whether businesses like it or not. Technological advances have made our machines and tools much more efficient. Much more relevant in our everyday lives and failing to integrate can cost more than doing so in the long run.

We, at Imaginationeering, are one agency in particular that can offer you this new service and even help in your transition. Offering a wide array of services involving new machine technology and bringing the future to you through advanced machining. Contact us to begin your journey in to the new world of technology today. Change is coming for everyone, and while some may adapt faster than others, at some point in the near future we all must adapt to thrive too. Whether it be big or small machining, CNC technology will soon be a must. So, gear up and get back on top of your game because if you haven’t integrated yet you are already falling behind.