CNC Milling and CNC Turning are two variations of the same service. They both are very popular and have effective ways to produce complex designs accurately. CNC stands for Computer Numerical Control. The main reason for using CNC services is that it can easily produce designs on hard materials like metals, steel with complete accuracy that is almost impossible to do on hand and other methods. Your product or parts are designed in a computer to create a 3D model. Based on your design and requirements, it will be either processed in a CNC Milling Shop or a CNC Turning Shop.

However, there is one drawback to the CNC process. You cannot process all kinds of metals in the CNC Machining Services.

So now that we know about CNC Machining Services, let us know about CNC Milling Service and CNC Turning Service.

What is CNC Milling?

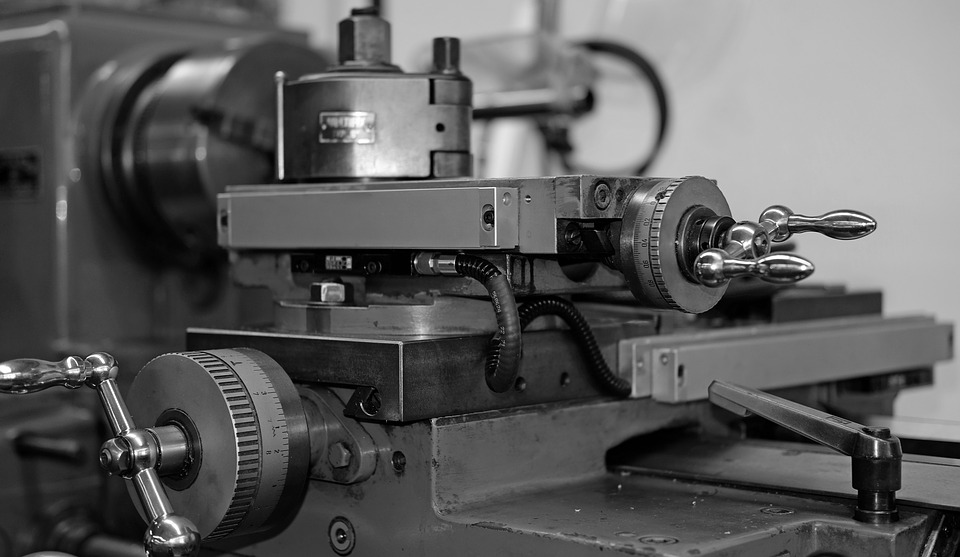

CNC Milling Services are used for complex designs that are asymmetrical or non-cylindrical in shape. You either take your 3D design into a CNC Milling Shop or the shop will design it for you. The model is then loaded into the computer of the CNC Milling machine. In CNC Milling, the computer uses a robotic hand with various kinds of rotary cutters to cut through the workpiece. The hand can move in different angles and axes freely, so does the table on which the workpiece is placed on. You also need to pick a material that is qualified to be processed in CNC Milling. You need to consider the tensile strength, hardness, friction, surface resistance, conductivity, and stress capacity. The CNC shop will do this bit of work for you and recommend you the idle materials you can use to build your product. The best materials you can use for CNC milling are Aluminium, Steel, Stainless Steel, Titanium, Brass, Bronze, Zinc, Copper, and also Magnesium. Some materials offer great stability and others conductivity and long-lasting properties. Whichever materials you pick from these, CNC Milling Shops can easily produce your product with great efficiency and accuracy, even for complex designs.

Now let us talk about CNC Turning Services.

What is CNC Turning Service?

CNC Turning is almost the same as CNC Milling. One notable difference is that CNC Turning does not use a robotic hand with rotary tools.

CNC Turning Services is mainly used for products or prototypes that have a cylindrical and symmetrical shape. In a CNC Turning Shop, they use a round piece of your desired material. Here, you have the option of picking wood for processing. Baseball bats are built using CNC Turning. So when the cylindrical workpiece is fitted into the machine, it starts to rotate at a great speed. There is a computer-controlled torrent hand with various kinds of blades or sometimes, it can hold a drilling tool for special products. The computer controls this torrent and feeds it to the workpiece to create the shape that was loaded into the computer before.

Now the other factor in the CNC turning service is the same as CNC milling. You need to create a 3D model of your product to load it on the computer. You need to consider several factors for picking up material for your workpiece. The factors you need to consider are friction, durability, stress resistance, friction resistance, etc. Besides, you need to consider the radius of your product or prototype. If the radius of your product is too less, it may break easily, or sometimes, the machines in some CNC Turning Shop, are not precise enough to process that.

Now let us look at the difference between CNC Milling Service and CNC Turning Service.

Difference between CNC Milling Service and CNC Turning Service

Rotary Blade & Rotary Workpiece

There are some notable differences between these two CNC Machining Services, but the most notable and key difference is that CNC Milling uses a robotic hand with rotary tools while CNC Turning uses a rotating workpiece.

Different Method of Removing & Shaping Materials

The workpiece in a CNC milling can also move and rotate in many angles and axes but not in great speed as the workpiece moves in CNC Turning. The CNC Milling tool primarily uses the rotary force of its robotic arm and the workpiece table rotates for assisting the milling process. But in CNC Turning, the machine uses the rotating force of the workpiece to cut and remove materials. The torrent hand holds a steady non-rotary blade and the computer controls the hand to feed the blade into the workpiece to create the desired product.

Types of Shapes

In CNC Milling, you can mill a workpiece and create products of any shape, both symmetrical and asymmetrical. It can create complex shapes that are impossible to do on hand with absolute precision.

But in CNC Turning, you can only produce cylindrical and symmetrical shapes. In some special cases, you can drill holes in the shape, but to be fair, CNC Turning has less functionality than CNC Milling.

Product Dimension Consideration

In CNC Milling, you don’t need to consider product dimensions. Rather, you need to mainly consider some factors about the workpiece material.

But in CNC Turning, you need to consider both workpiece material and product dimension. You mainly need to consider the product radius. If the product design is too narrow, it may break from the rotating force of the machine.

Conclusion

So, these were the main differences between CNC Milling Services and CNC Turning Services. If you ask us which one is the best, we would say CNC Milling hands down. Because, in CNC milling, you can create products with different shapes. From asymmetrical to symmetrical and round shape products. But if you just want a machine to create cylindrical and symmetrical products, you can go for CNC Turning.