Precision Machining is a key element of manufacturing companies. Almost all the modern machines and equipment that big companies and we, regular public consumers, use have something to do with precision machining. Private vehicles, public transports, computers, smartphones, electronics, etc. all need precision machining. Without precision machining, they are possible to build but it will cost way more and businesses today are all about reducing cost. The main target of businesses today is to reduce manufacturing costs and increase their profit. The manufacturing companies need to stay competitive in this dynamic marketing environment to be profitable and also, they need smart ways to reduce the manufacturing cost of the new products. Also, they need these parts to be produced as quickly and timely as possible. The smart way to hit all of these checkboxes is to contact a high-quality expert precision machining shop for their services.

How can a Precision Machine Shop help your business?

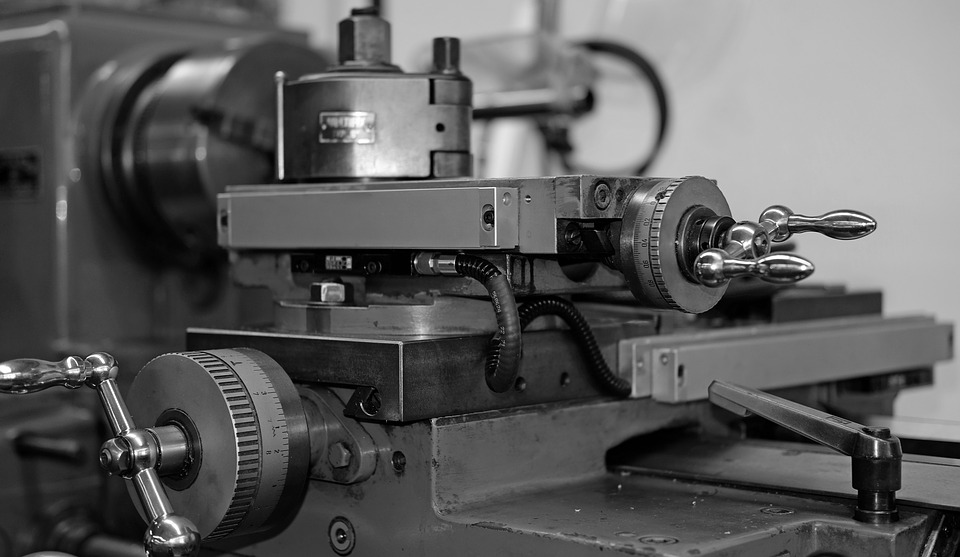

Hiring a Precision Machining Service is an effective way to reduce your manufacturing cost. What do they do? They use different types of machines and subtractive processes to produce different kinds of parts for your business with great precision. As a result, your business will have fewer errors in manufacturing and produce a great number of products in less time.

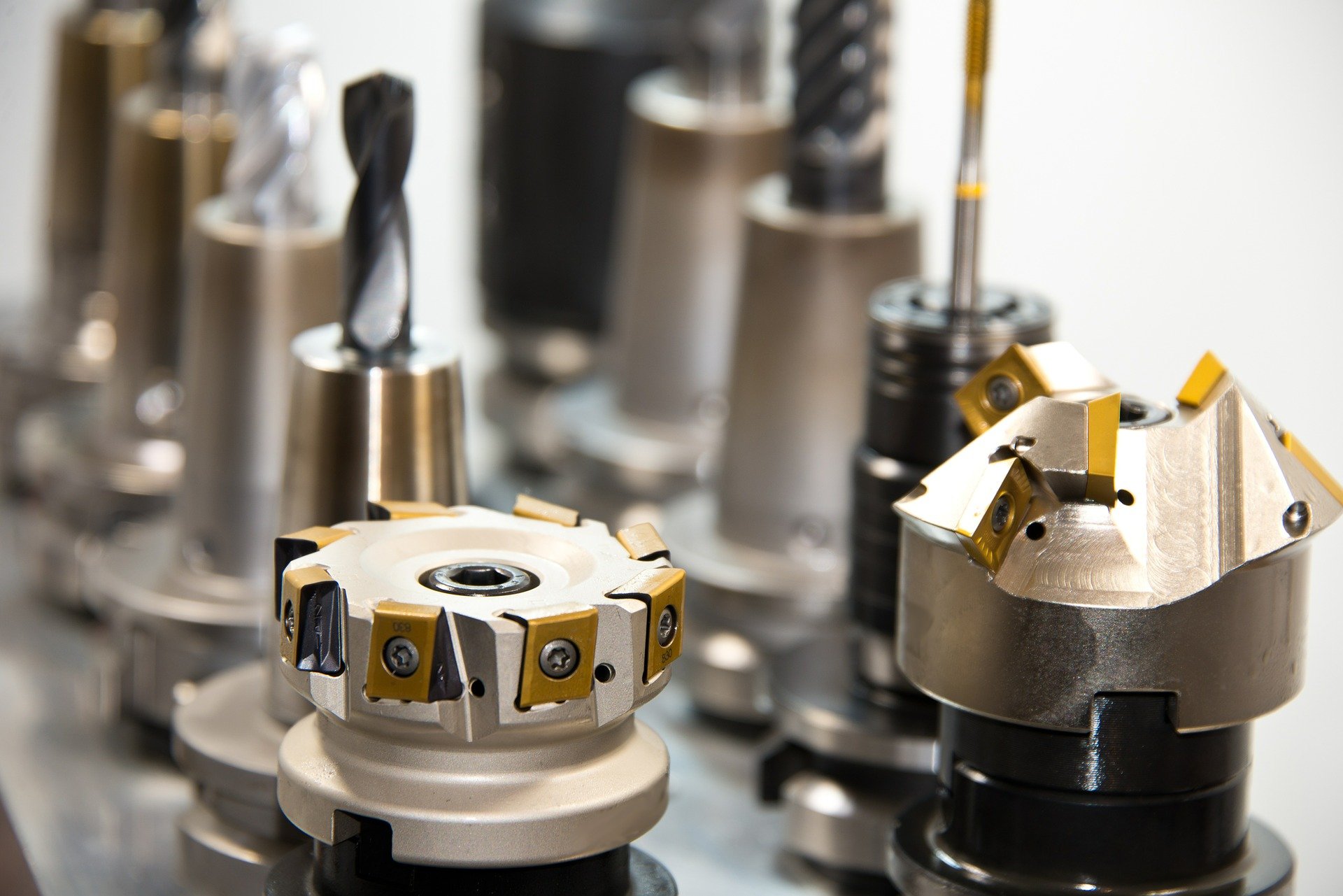

You can expect to see different types of tools in a precision machine shop, including drilling, sawing, CNC machines, etc.

Problem with in-house precision machine shops

Now if your company can build their precision shop and they don’t want to hire any external services, then think again. Precision machining is not child’s play. It requires years of experience and teams of experts in designing and machine handling. If your company builds an in-house precision machine shop, it is likely to hire new workers at low wages to reduce cost. But the thing is, these new workers will likely struggle with these precision machines. Because of that, you will get many errors in manufacturing and fail to maintain punctuality.

Benefits of hiring precision machining services

Now let’s talk about the actual benefits that your company will enjoy by hiring a precision machine service.

Precision/ Accuracy

The first benefit of precision machine services in its name, precision. Precision shops have various types of machines that are programmed and operated by computers. With computers involved, there is no room for deviation and errors. These shops are all about accuracy in production, that’s why they have trained expert workers for machines that need human involvement for processing. Their team of expert workers and powerful computers will produce your products and parts with great accuracy. It is impossible to find any notable deviation in their machined products.

Custom Machine Shops

Sometimes your business needs custom design parts for new product development. These are mainly called prototypes and they are experimental. So, they need different types of custom parts to build by testing and through testing, designers select parts for mass production. So before pushing them on mass manufacturing, your business needs a way to precisely produce a few units of these parts for testing. And the good news is that precision machining shops do that. With their custom machine shops, precision machine services can build your custom parts for testing at a very low cost. This is called custom machining services.

Punctuality

Another benefit of hiring the services of precision shops is their timeliness. The modern industry market is very dynamic. The products and designs that are on-demand today can be replaced in a matter of days. That is why all manufacturing companies need a quick and effective way for producing new parts and equipment for ensuring their survival in the market.

Hiring a precision machining shop is the best way to produce new parts quickly without any error. So that is the second benefit of precision machining services.

Reduced Cost

The main motive of all businesses is to reduce their cost of manufacturing and production. There are some other ways to manufacture parts for your products using other methods. But they cost more in case of time and money. And if your business wants to build its precision shop for manufacturing, then it will have errors in production due to a lack of expert and trained workers.

So the best option is to hire an expert precision shop. They can produce your desired units of products in days and help your business survive the dynamic market environment.

Expertise

Precision machining is all about accuracy and accuracy is not child’s play. It needs years of experience and trained workers, designers, and computer programmers. Which is not likely to be seen in an in-house precision shop. Without teams of experts, your company’s in-house precision shop will likely create error products and many deviations in their dimensions. This will cost you time and waste of materials. The main motive of a precision shop is to save your cost and time.

Conclusion

So, these are the expected benefits your business can get from a precision machining shop. So, you should reconsider your decision of an in-house precision shop and rather hire the service of experts.