It’s no surprise that a CNC machine shop offers plenty of CNC milling services and CNC turning services along with cutting-edge techniques to batch produce your precision machine components.

However, if you’re not well-versed in CNC machining terminologies, it may lead to poor choices.

In case of a specific manufacturing requirement at a CNC milling shop or CNC turning shop, for example, it makes sense to understand the difference between CNC milling and CNC turning.

Knowing the difference can help you to make the best purchase decision for your application yielding better results and faster part creation.

To make things easier, we have compiled an entire blog to make things clearer for you to understand.

Ready? Let’s dig in!

What’s the Difference Between CNC Milling and CNC Turning?

Before you go ahead to learn what sets the two apart, let’s understand each machining operation in detail.

What is CNC Milling?

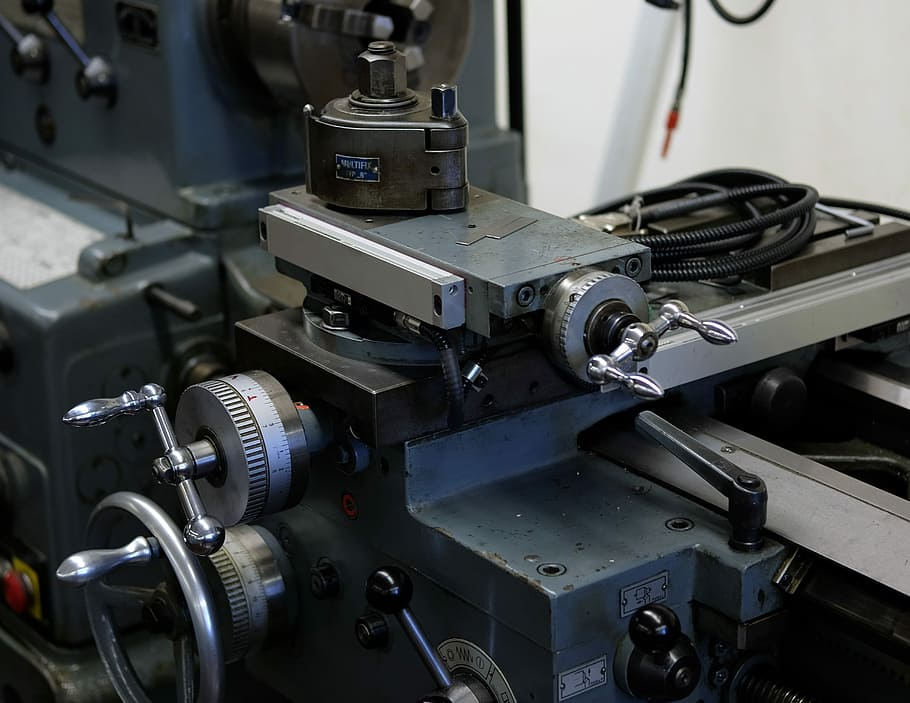

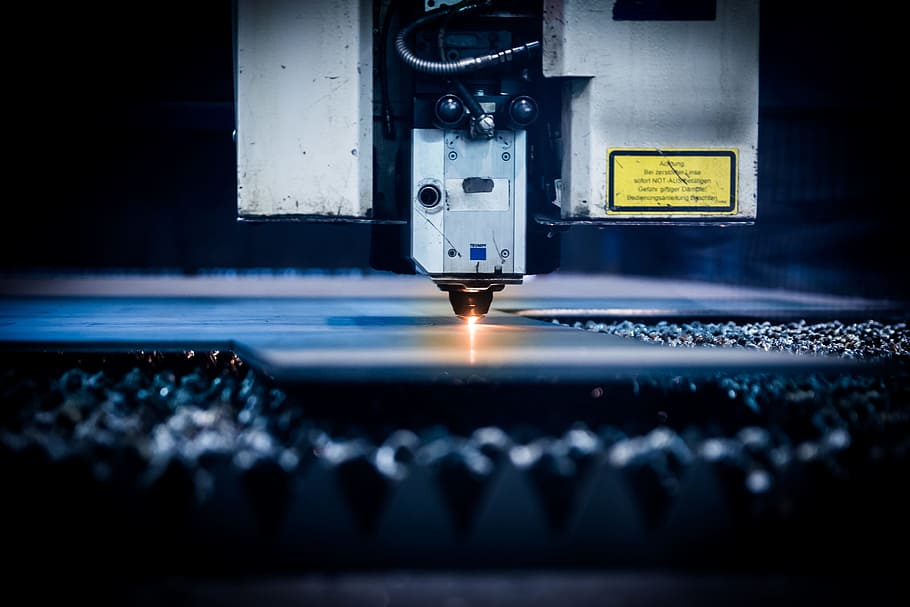

CNC milling or ‘Computer Numerical Control Milling’ is a type of machining process that uses a rotating cylindrical ad multi-point tool known as ‘Milling Cutter’ to remove material from the workpiece to produce a part of precise dimension.

The milling operation is computer controlled and is performed by dedicated CNC mills in varying directions on several axes, cutter head speed, and pressure.

Based on the requirements, machinists carry out different operations such as plain milling, face milling, side milling, angular milling, and more to bring out the exact form factor for the part.

What is CNC Turning?

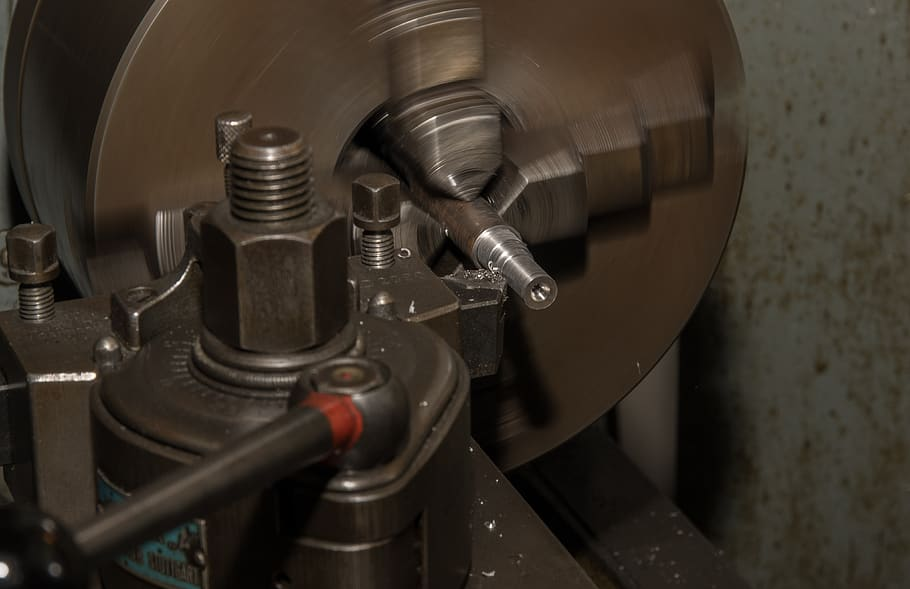

CNC Turning, on the other hand, is also a type of manufacturing process. In this, the workpiece is held in a device called ‘Chuck’ and is rotated or ‘turned’ while a single-point cutting or boring tool cuts the piece to form a shape of the desired scale.

Like CNC Milling, the turning operation in CNC Turning is also computer programmed and requires minimal supervision, unlike manual lathe machines.

The Difference

While the core purpose of the two is to remove or subtract material from the workpiece, CNC milling and CNC turning differ greatly in how they operate to machine a particular part.

In cnc milling operations, the machine rotates the cutting tool while the workpiece stays stationary whereas in turning operations the workpiece is rotated while the stationary cutting tool performs the operation.

However, that’s not the only difference between the two. Both CNC Milling and Turning are used for producing different types of end parts.

For parts that need to have complex shapes that include squares or custom ones, CNC milling is preferred. On the other hand, for parts that require symmetrical and cylindrical shapes turning process is used.

Even though CNC Milling and CNC Turning produce completely different results they allow you to carve out patterns and details that are impossible to achieve by hand. By leveraging the power of both, you can precision machine almost any part as per your desire.

Where is CNC Milling and CNC Turning Ideally Used?

Due to the differences mentioned above, CNC Milling and CNC Turning both have different applications.

In spite of their differences, Precision CNC Milling and Precision CNC turning are utilized for creating regular as well as custom-built parts and can precision machine a wide variety of materials like plastics, metals, glass, wood, etc.

With respect to Precision CNC Milling, it is used in making anything from cabinets and furniture, woodworking to aluminum machining, prototyping, and sculpting.

Thanks to its ability to create cylindrical parts, Precision CNC Turning is best used for creating items such as bowls, crankshafts, dining room table and chair legs, gun barrels, etc.

CNC Milling and Turning is also suitable for a wide range of industries and used in everything from Aerospace to Oil & Gas and more.

What Factors Can Impact the Production of My Part?

When it comes to short-volume runs, CNC centers are best suited for parts that fall under the range of 2.5” OD. On the contrary, turning centers are ideal for parts that go an upward of 2.5” OD, though that also depends on the volume being produced.

Also, remember that dimensions play a crucial role in part turning. If your part falls under 1.25” OD it is assumed that turning might not be the best option for producing that part.

Another thing to note is that different types of CNC Centers provide different tooling options which dramatically could impact your part production. Things like the diameter limitations, power, volume, and speed specifications can also impact the overall cost of the part being made.

Final Thoughts

Well, now that you know the difference between CNC Milling Shop and CNC Turning Shop you can safely pick the ideal method for your part manufacturing and bring out the best results.

If you’re not aware of what method works best for producing your part, you can always seek the opinion of expert machinists that can guide during each step of CNC milling and CNC turning.

The best part? You don’t even have to look for one.

We are a CNC milling Shop and CNC turning shop based in Houston, Texas that specializes in providing excellent CNC milling services and CNC turning services for major industries.

With our robust CNC mill Machines and CNC Turn machines, we can machine any type of part with extreme accuracy and tight tolerances.