Since its introduction in 1940, Computerized Numerical Control, or CNC Machining has become the most used tool in almost every manufacturing industry. It stands as a proud reminder of how long we’ve come in manufacturing technology.

That being said, let’s have a look at how CNC machining has become synonymous with modern-day manufacturing.

Here are the 5 qualities that make CNC machining the ultimate manufacturing tool of today’s era.

1: Automation

The most striking feature of CNC machining is its automation capacity. With simple commands and data input, you can manufacture a variety of products in a short time.

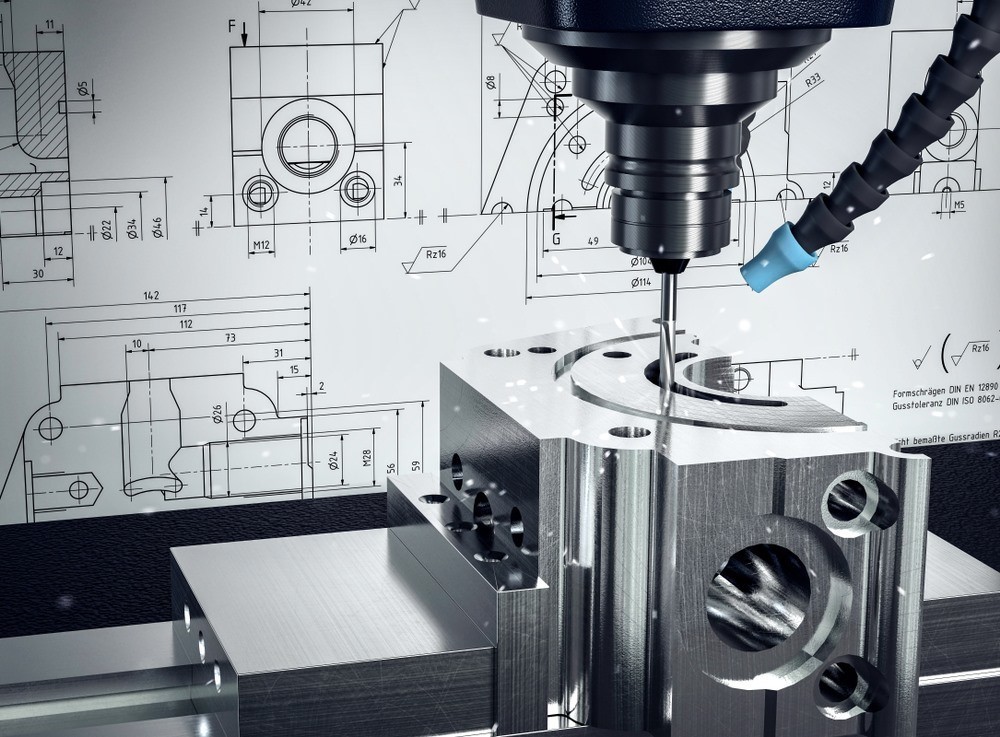

CNC machines are designed to process numerical data to use electro-mechanical equipment so that they can change the shape and dimensions of the raw material. This significantly reduced the time and increased the rate of manufacturing.

Also, automation has significantly reduced human efforts as a single person can manufacture thousands of products within a day.

These machines carry out a plethora of specialized tasks like lathe, plasma and laser cutting, milling, etc. From custom parts to complete product manufacturing, CNC machines have become the most reliable bulk manufacturing tool for every industry.

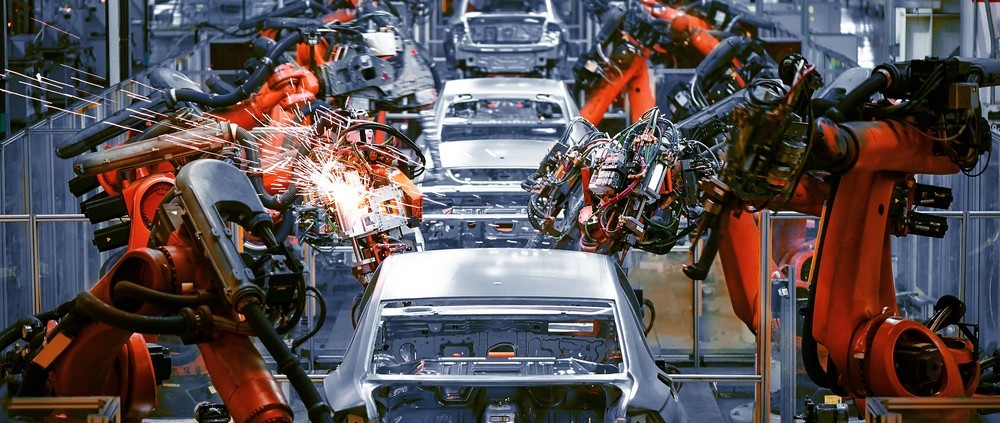

For instance, the automobile industry can manufacture cars in bulk using CNC machine features like custom metal fabrication, paint coating, manufacturing supporting parts and creating a functional prototype. It also reduces the time between product designing and manufacturing the final product.

2: Accuracy

Before CNC machining, manufacturing was mostly done by human labor which was prone to errors and miscalculations. Also, the rate at which products were getting manufactured was significantly lower. That was the main reason why CNC machining came into existence.

As it works on a pre-set computerized commands, it can work tirelessly to manufacture products in bulk with extreme accuracy.

The only time it might create a faulty product is if there are some errors in command input, or problems in the hardware itself, which can be rectified easily.

CNC machines are used in industries where precision is crucial for the product. For instance, medical equipment, automobiles, and aircraft require high precision in manufacturing to make a quality product. Any error in manufacturing can cause product malfunction that may even cost a person’s life.

All these factors make CNC machining an ideal choice for rapid manufacturing with minimal errors.

3: Customization

CNC machines provide the ultimate customization for product dimensions and carry out a variety of tasks.

All you have to do is change a few specifications in your data input and the CNC machine will create a product with various dimensions.

These machines also come in a variety of specializations like 3D printers, custom lathe and mills, precision cutting, etc. which makes it the perfect subtractive manufacturing equipment for every machine workshop.

Industries usually need to make a few tweaks in the raw material processing to save on costs and increase the production rate. With CNC machining, you can do it without stopping the entire manufacturing process.

4: Bulk Manufacturing

As I’ve mentioned before, CNC machining has accelerated the manufacturing rate by thousandfolds. If your product requires bulk manufacturing of various parts and accessories, CNC machining is ideal for you.

Every company wants to increase its production and release products in the market as soon as possible. CNC machining gives you a first-mover advantage and creates a steady buffer of finished products.

5: Guideline for Future Technologies

CNC machines are the earliest innovation that changed the entire landscape of manufacturing. It has made product manufacturing much easier, cheaper, and faster.

However, the most important thing it did is to lay a foundation and benchmark for every manufacturing equipment of the future.

We’ve seen shifting paradigms in manufacturing technology since the first industrial revolution. Technology has improved drastically in the past few decades. But the only thing that remained constant was the presence of CNC machines.

Every new manufacturing tools made in the past few decades had CNC machines as a first outline. This new product should work as good as the traditional CNC machines if not better. CNC machines have opened tremendous possibilities in production technology.

The modern CNC machines are now equipped with an interactive display with a touch screen, user-friendly interface, a higher degree of customization, and the ability to work on various products at once.

Bottom line: CNC machines have transformed the manufacturing industry and set the right path for the future of product manufacturing technologies.

Final Thoughts

To sum it all up, no matter what kind of products you manufacture, CNC machining will be the inseparable part of your manufacturing workshop.

Don’t have a CNC machine shop of your own? Well, you do now. We are among the leading CNC precision machine shop and more than happy to help all the manufacturers in Houston, Texas.

Take a look at our variety of CNC manufacturing services to find out what can we do for you.