To design a machine part is no mean feat without a machine shop. With several machine shops spread around, there is the temptation to walk into just anyone for your product.

Well, there is the right one for your product if you know the knack for finding it. However, how can you do this? Not to worry! Here are the ways to find the right machine shop for your product.

Service Coverage

Many machine shops can offer a wide range of services while others are specialized. That means, they can do only some kind of job. Hence, if your product does not fall in line with the service they provide, there’s no need to take your task there.

Services machining companies are a dab hand at producing prototypes of designs, equipment repair, and production of items.

Machining companies vary in specializations and material usage. Some of the materials used in these companies are plastics, alloys, glass, rubber, wood, and metals. So, once you know the area of expertise of the companies, it becomes easier to make a choice.

Organizational History

There is a need to know the history of the factory. You should know how long they have been in operation, their customer satisfaction level, and their financial stance.

Machining companies with a robust financial base are very much likely to provide a satisfactory result than their counterparts. It also enables them to make prompt adjustments and technology updates whenever the need arises. An ideal Texas machine shop should source for finance beyond money paid by clients.

Moreover, it should be a point of interest to know if they have done similar works like yours over the years. That settled; you can ask for a sample. If you like the quality of what you see, you can have the same for your product.

Staffing

Of course, you won’t want your work to be the trial of people’s skills. The shop must have workers with the experience and expertise to deliver according to your taste. While most machines would run on CNC, the place of human interpretation and direction is ever so important.

The staff should include competent machine operators and manufacturing engineers who can adapt and evolve according to the task.

Besides, there is a need for a good customer service team. Are they calm, cooperative, or only eager to take up your work for monetary gain? These are signals to knowing if they would be able to help you or not. Several Houston machine shops have a good reputation for excellent customer service.

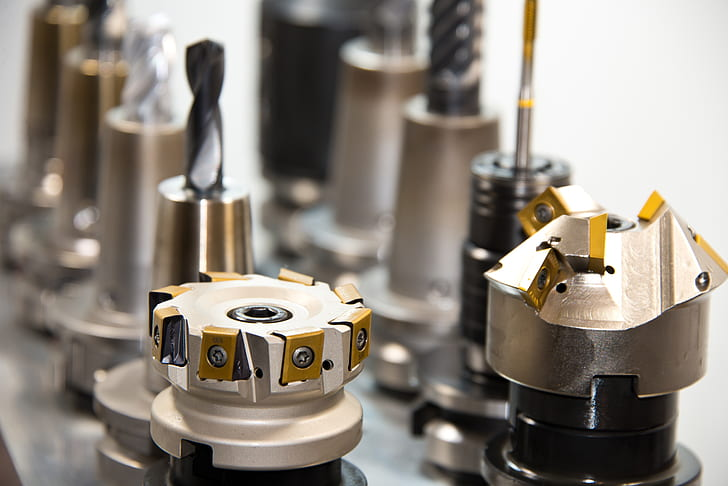

Machine Availability

A few lathes and drills are not enough to win your trust. A standard shop should have varieties of machines so that diverse operations can take place within the location. That said, you should expect to see some lathes, mills, centers, multitasking machines, drill presses, grinders, and much more in diversities. There is an expectation that many of them should run with computer numerical control (CNC) and other technologies.

You wouldn’t have any problem with an average Texas machine shop on this issue. Failure to do this could imply that they would end up subletting certain parts of the work to another machine shop Texas bound.

Feedbacks from Clients

There is no way you can do without this. It is a crucial consideration in determining if a place is right for your work. What do previous clients have to say about them?

A Houston machine shop would have a feedback platform that is accessible to the public. While you can’t make shared opinions the sole basis of your decision, it would be unwise to overlook them too.

Certification and Registration

There is a whole lot of difference between outlets that have both registration and certifications from the ISO, FDA, and ITAR. If it isn’t indicated on the workplace’s website or in the building, you should ask the manager.

Why this is important is that it assures you that they use only high-quality materials for their job. Also, the certification is a guarantee that you are in the right and efficient place for your project.

Privacy

How well does the company manage its customer’s data? This consideration becomes most important when the product is your invention. One of the documents you should ask them to sign before engaging them is the Non-Disclosure Agreement. That guarantees you that there would be no leak of your patent. A Houston machine shop would expect nothing less than that from you.

Timeliness

Most machining companies will do everything possible to win you over despite their tight schedule. The onus is on you to know how quickly you want your products to be ready. If it is urgent, then you should look for another.

With the number of Houston machine shops, your search won’t take forever. Delivery when due is a crucial consideration in matters of service.

Pricing

The pricing of machine shops must not be unbearable. Any machine shop Texas found would have a price listing. It is beneficial to do a price sampling from several shops.

You must also be willing to pay for quality performance, lest the cheap cost of some deters you from checking out the other pertinent requirements. Hence, the price should be the final consideration after every other area has checked well with you.

Final Thoughts

Making the right decision in finding a machine shop is fundamental to getting good results. Doubtlessly, finding the best machine factory for your product would take some time and patience. The good thing is that in the end, it’s worth it.

Ultimately, if your product must materialize satisfactorily, the bulk of the work lies with you. Although affordable pricing is essential, quality output should always be the priority.