No one planned for it, but it came nevertheless. The world as we know it would never be the same after it took a big hit from the Covid-19 virus. So widespread was the impact that every industry has a tale to tell.

Losses were epic, and the laws of supply and demand were pushed to the limit to overcome the trying times. Maintenance schedules didn’t matter, as staying safe became the immediate goal.

However, as there is a gradual opening of economic activities, it becomes expedient for industries to gain stability. While several factors could get them back on their feet, quick turnaround machining would play an immense role.

This article will look into how quick turnaround machining can help to steady industries after the pandemic.

What is quick turnaround machining?

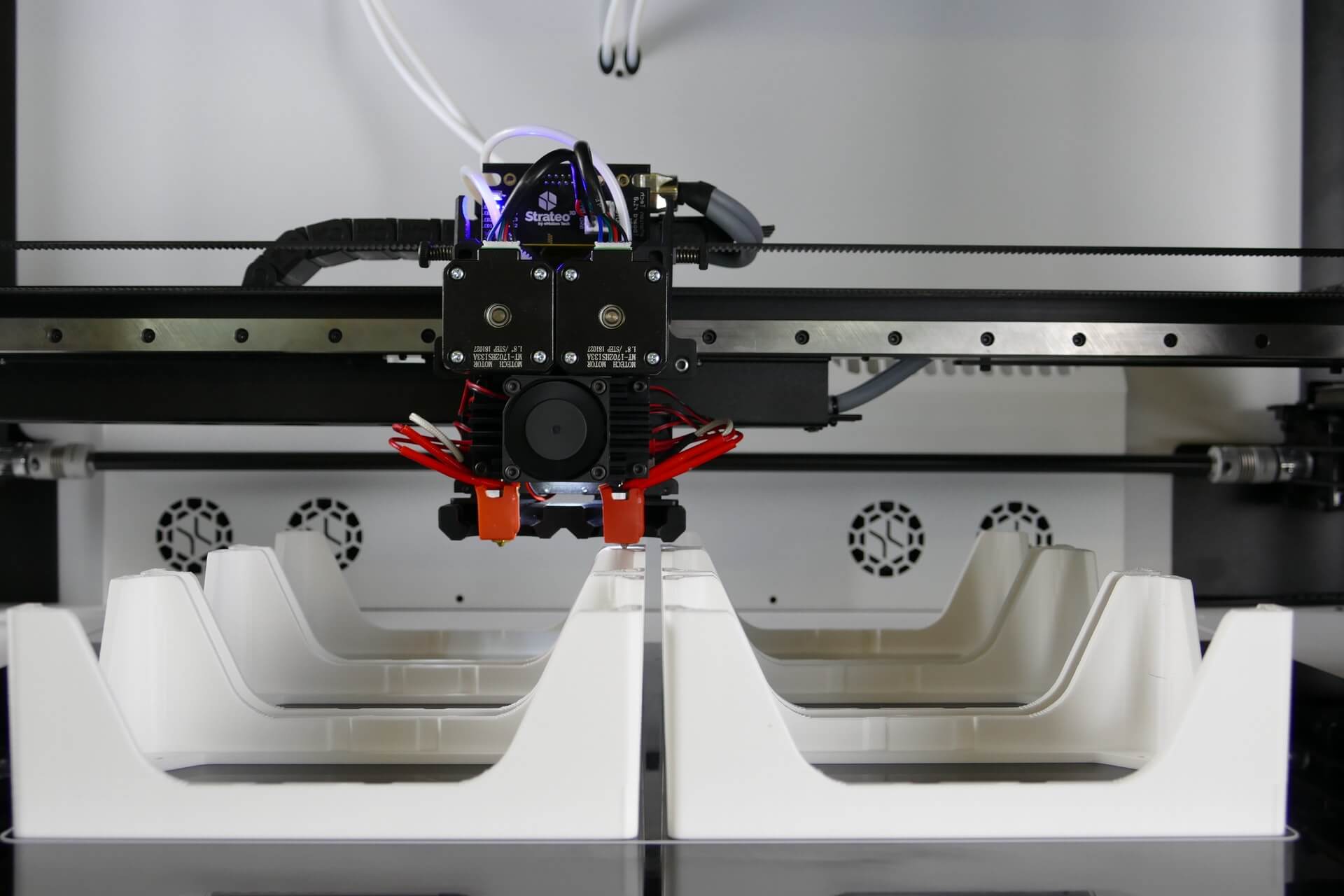

Quick turnaround machining refers to the services of machine shops with the capacity to reduce lead times. More so, it involves preparing and responding to the emergency needs of clients.

Houston machine shops provide this service to a wide range of industries. Knowing that needs show up at an unplanned time, they have several machinery and professionals who interpret problems and provide apt solutions.

Besides, these companies usually stock up materials that are commonly used. The practice further reduces lead times. Companies in need of custom-made and non-standard parts can get what they need in times as little as a day. Other services they offer include maintenance,

Phases of Industrial Stability

According to studies, there are three expedient phases industries must navigate before attaining industrial stability. These include technical, psychological, and economic phases. Quick turnaround services can help to achieve these needs, as we would see in a moment.

A. Technical phases

Machines have been highly efficient in tackling production issues. Lags due to human variables are in many ways minimized using CNC machining service. Since the bulk of the work lies on program writing and execution by a computer, these variables are absentia.

The advanced technology of CNC machining services bypasses the often tedious processes that manual engineering pose to regaining balance. Not only does this technology get the production wheel rolling, it makes it do so fast.

B. Psychological phases

The concept of psychological balance covers both clients and manufacturers. Quick turnaround machining would doubtlessly reduce conflict between both parties. Nothing else would boost confidence after a prolonged period of inactivity than covering much ground in little time.

As a result, both sides would sooner share the can-do spirit, vital to propelling the industry.

C. Economic phases

Finance is a crucial industrial aspect. Minimizing losses and maximizing profits should be the priority of companies looking to rise from previous setbacks. Also, they must increase in capacity to handle several customers at a time.

Without a doubt, companies offering CNC machining services are playing their part in ensuring a fast turnaround for multiple works. The swift turnaround eventually keeps industries at work. That means they can dare to do more than ever before to cover lost grounds.

Why do industries need stability as a matter of urgency?

Industrial stability is the key to a functioning economy. No nation in the world can thrive without industries. Some of these challenges are a result of

1. There is an increased need for maintenance

Perhaps you are just about to open up your manufacturing firm after a long period of hibernation. While it is good news, there is the fear that some machines may have picked up a fault due to unuse and absence of maintenance. Getting those parts back to work or replacing them on time should be your concern. Finding a spare may prove difficult due to the use of custom parts or general unavailability. For that, there is a need for machine shops with fast machining services.

2. Industries are racing against time

As industries are trying to jump-start their activities, there is the need to make up for lost grounds. The backlogs are there, and so are the new demands. As a result, you would have a longer operation time than before.

The scenario would not be overwhelming to employees alone but the machines as well. There’ll be a need to keep engines in optimum condition at all times. For this, quick turnaround machining is indispensable, and there are Houston machine shops on the ready.

Meanwhile, the fallow period of activities has also been a chance for several industries to go back to the drawing board. As a result, there are continuous hurdles to scale.

3. There is a need to reduce cost

The period of inactivity brought about much loss to companies. Managing available funds for production would be a cogent issue in times such time as we are.

The longer the production time, the more the financial implication. The rapid time for producing machine parts helps reduce expenses. Again, products must get to the market at the right time for optimum sales. Industries know this too well and so work to reduce production time.

To do this, they need fast machining services to meet the increased need for pieces of machinery. Machine shops in Houston have the expertise and equipment to serve various industries all in good time.

Bottom Line

There is no need to reiterate the importance of industries to the economic development of any nation. Getting them up and working is not a matter of deliberation but that of urgency. Houston machine shops are taking the lead to make this happen by providing quick turnaround machining with a view to steadying industrial growth in these post-pandemic times.