Finite Element Analysis (FEA) is one of the tools that has developed over the ages to extensively verify, validate and optimize the performance of ideas or products under structural loads and conditions. FEA is very useful especially for validating the strength and stability of the design under actual loading conditions. One of the primary areas whereas FEA is growing is in the Additive Manufacturing of various product designs which are specifically tailored for particular industries and applications. Additive manufacturing (AM), also known as 3D printing, is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems. This method has been used for fabricating and forming net and near net shape components for different industries such as aerospace, biomedical, and automobile applications.

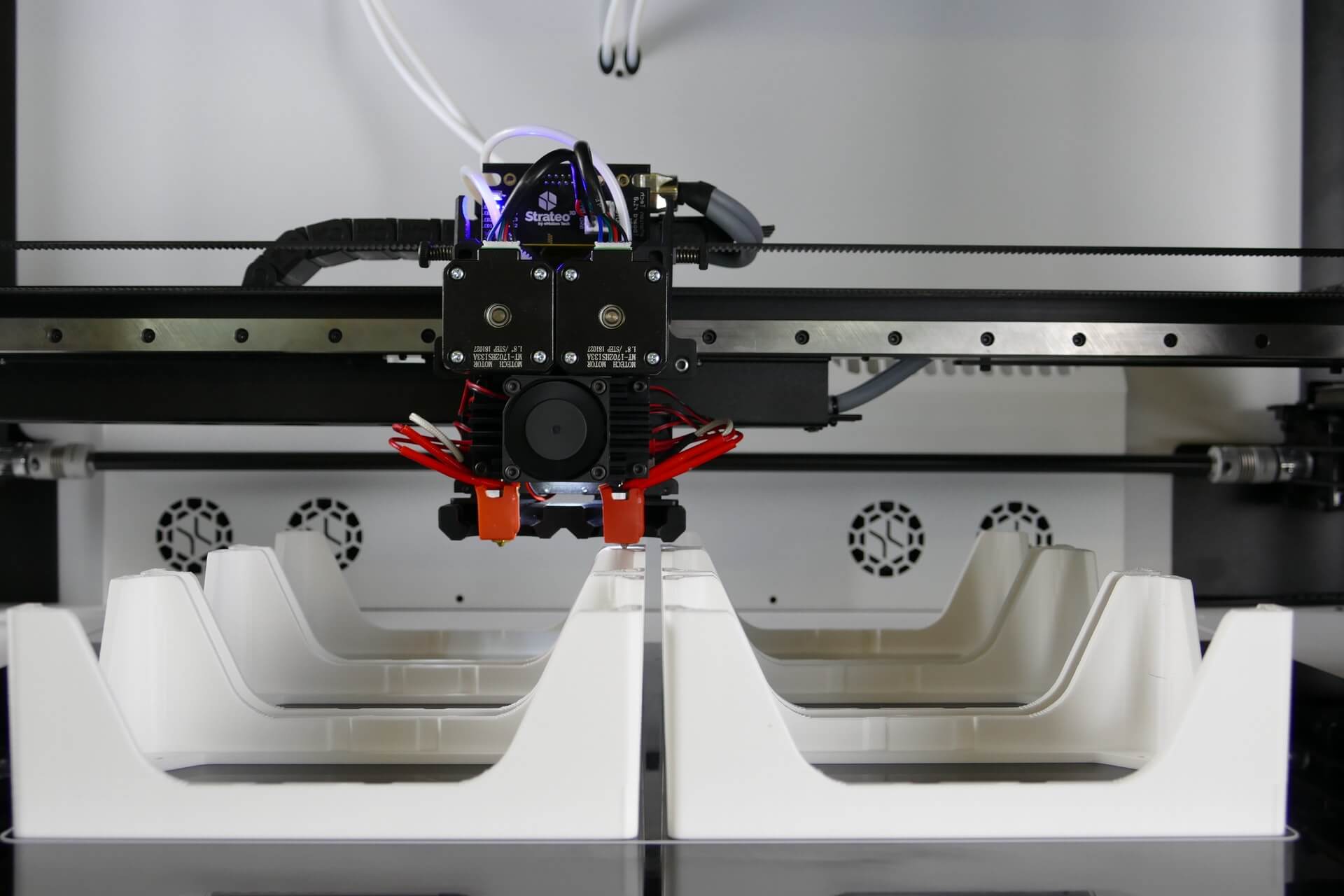

The AM process normally includes the heating, melting, and solidification cycles of a material in the form of a feeding wire or powder using an electron or laser beam which provides high-density energy to melt the material in a fraction of time. Various FEA services are paving the way for additive manufacturing by designing the components such as calculating the thermal expansion and internal stresses in the 3D printed components as well as making sure that the failure due to the same does not happen during the life of the component for the application. Due to FEA analysis services, many complex components can be easily developed with high precision to the point that nowadays most machine shops have 3D printing machines to print a plethora of high-quality 3D parts. Due to the availability of various 3D printing materials, various CNC machining services are offering clients to produce parts of any desired mechanical and chemical properties. Furthermore, combining 3D printing machines with conventional machining capabilities has led to a reduction in lead times, reduction in cost, and development of new product designs and processes in several industries. It has led to 24-hour machine shops where the 3D printing machines in the machine shop can be used throughout day and night to print various simple as well as complex components.

Additive Manufacturing has become a continuous trend in the industry. The main advantages of machine shops offering additive manufacturing services lie in a continuous expansion in the range of metals, alloys, and metallic composites which can be produced in this technology. Combining Additive manufacturing services with FEA services is very advantageous in the faster transition of components from the design stage to the product of the final part. As additive manufacturing and CNC machining services provide flexibility in the design and development of the part, FEA services provide insights to the manufacturers and clients about the strength of the product design as well as give an idea for improving the process for mass manufacturing of the part. Usually, no specific tools or machining devices are required to process the part after it is 3D printed. The machine shop only needs to remove elements such as support structures, created during the printing process. This allows to significantly decrease the post-processing time. Once the part is developed, FEA analysis services ensure there is no failure due to the removal of material. In presence of failure also, it becomes easier to change the process and repeat the 3D print in a shorter time enabling the manufacturer to rapidly prototype, analyze and modify until the final part is reached. Therefore, additive manufacturing of metal parts translates into shortening lead times to days instead of weeks.

Another advantage resulting from producing metal with workshops offering additive manufacturing services is a reduction in material waste. In additive manufacturing, raw material is added and formed layer by layer, rather than subtracted or cut out of a bulk solid figure. Therefore, the material is placed only where needed, and the cost of the primary material used to produce one component is reduced. That makes 3D printing a resource-efficient technology. This not only ensures an optimized weight of the part, but also a strong part that can sustain an equal amount of stress as the original part using FEA services. It may be beneficial for automotive and aerospace applications.

Looking at metal parts from a designer perspective, machine shops in Houston with additive manufacturing allow for the production of unique and complex structures. Traditionally, some elements which cannot be cast need to be added to the element in post-production. For instance, adding the holes and threads requires machining capabilities after removing them from the mold. That increases the time and effort needed to manufacture the desired shape. On account of additive manufacturing, the complexity of the part does not generate additional costs. Where it was previously necessary to use several separate parts within a twisted or welded structure, now just one part is required. And it can be manufactured as a single piece. Therefore, newer product designs and processes are possible on parts that can be turned and shaped as per the client’s requirement. Using FEA services on the new product design further makes sure that there aren’t any thermal deformities being developed in the part as well as any internal stresses which can further lead to the failure of the part.

While additive manufacturing seems new to many, it has actually been around for several decades. In the right applications, additive manufacturing delivers a perfect trifecta of improved performance, complex geometries, and simplified fabrication. And along with FEA, Additive manufacturing is leading the way for the next generation of manufacturing and mass production by making even the development of complex parts and processes possible.