Blog

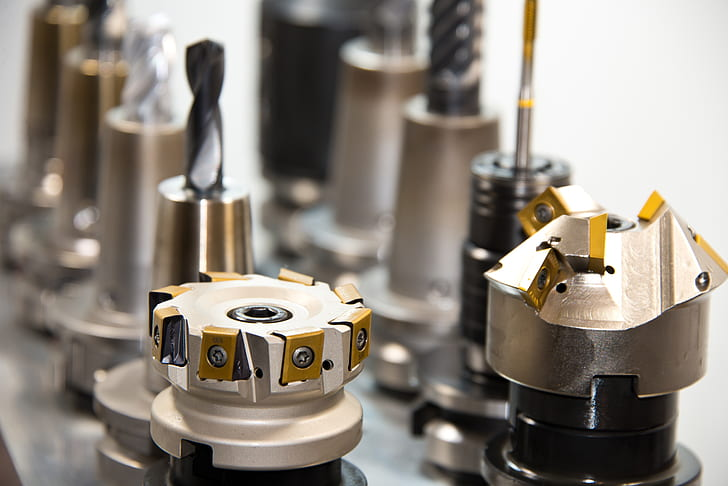

WHAT IS CARBIDE MACHINING AND HOW CARBIDE TOOLS ARE MADE?

Carbide is one of the most valued materials in the engineering world. The material results from combining carbon with a metallic or semi-metallic element. Although not as popular as iron and steel, the material is equally used in making engineering tools and equipment. Common examples of carbide applications are the production of cutting, drilling, grinding,…

HOW ER MACHINING IS PAVING WAY WITH AEROSPACE MACHINING

Aerospace Machining unlike typical CNC machining processes are characterized by tighter tolerances and more difficult to machine materials. Along with large five-axis machines, turn-mill machines and precision grinders are among the high-value machine tools routinely used in this sector. Materials typical of aerospace machining include lightweight aluminum for structural members; hard and temperature-resistant metals including…

QUICK TURN AROUND MACHINING: A KEY TO STABILIZING INDUSTRIES IN A POST-PANDEMIC ERA

No one planned for it, but it came nevertheless. The world as we know it would never be the same after it took a big hit from the Covid-19 virus. So widespread was the impact that every industry has a tale to tell. Losses were epic, and the laws of supply and demand were pushed…

PLACE OF MACHINE SHOPS IN ECONOMIC RESCUE POST-COVID19-ERA

The impact of the Covid-19 on humanity would not wear off as quickly as it came. The death toll has long surpassed the four million mark, and it’s still counting. Besides the annihilation of lives, the pandemic has also been an economic vampire setting several nations many years back economically. The world, needless to say,…

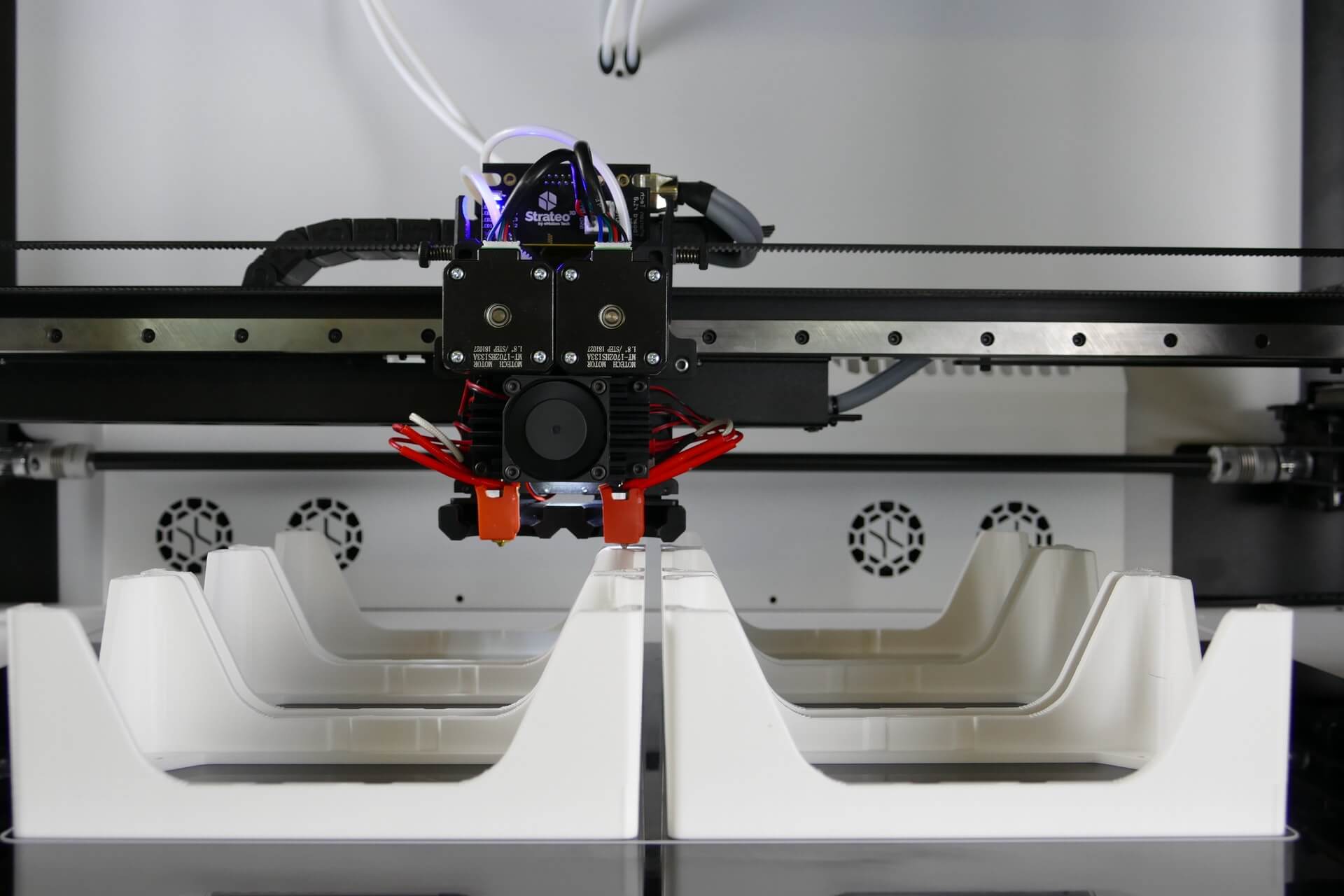

HOW FEA AND ADDITIVE MANUFACTURING IS PAVING THE WAY FOR NEW PRODUCT DESIGN

Finite Element Analysis (FEA) is one of the tools that has developed over the ages to extensively verify, validate and optimize the performance of ideas or products under structural loads and conditions. FEA is very useful especially for validating the strength and stability of the design under actual loading conditions. One of the primary areas…

BENEFITS OF PRECISION MACHINING FOR OIL & GAS INDUSTRIES

Machining is nothing new to the human race. It’s been practiced for over a millennium. Ancient Egypt was known to use machine tools as far back as 1200 BC. Although these were handcrafted, they gave them an advantage in ancient civilization. As expected, those periods were notable for dimensional errors when machine parts were made. Centuries…

HOW BUSINESSES CAN BENEFIT FROM CUSTOM MACHINING SERVICES

Machining is a process in which a material (often metal) is cut into a desired final shape and size by a controlled material removal process. The processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing in distinction from processes of controlled material addition, which are known as additive…

WHY CHOOSE ER MACHINING AS YOUR MANUFACTURING PARTNER

If you want to create a product or are considering wide-based production, you definitely want to build a product of value. You are likely on a quest for a manufacturing partner that will offer quality industrial manufacturing and standard parts, and produce the desired results. CNC machining is paramount for great quality prototyping and production.…

HOW TO FIND THE RIGHT MACHINE SHOP FOR YOUR PRODUCT

To design a machine part is no mean feat without a machine shop. With several machine shops spread around, there is the temptation to walk into just anyone for your product. Well, there is the right one for your product if you know the knack for finding it. However, how can you do this? Not…

QUICK TIPS TO FOLLOW DURING MACHINE BREAKDOWN

Machines are a replacement of human labor not because it gets the work done faster, but continuously too. A simple breakdown can cause loss of the entire operation and production until the flaw has been repaired. This downtime not only causes loss of working hours but also loss of money. According to the ARC Advisory…