If you want to manufacture a part at a CNC machine shop but not sure about the right process, things can get a bit confusing. Especially if you’re new to the world of CNC machining services.

But hey, good news! It’s not that difficult.

For starters just remember that there are certain automated techniques machinists use to manufacture your parts.

The most common of them are CNC Milling and CNC Turning.

Either one has its own specific purpose and there is no competition between the two. This means understanding CNC Turning is as much important as understanding CNC Milling.

As this post is about CNC Turning, let’s dig in to find out what makes it so important for manufacturing.

What is CNC Turning?

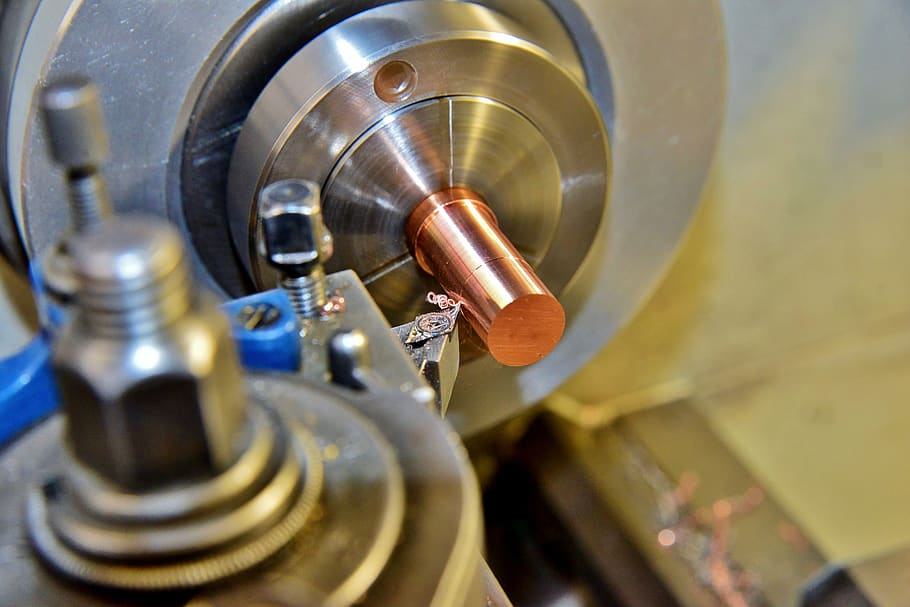

Computer Numerical Control Turning (also known as CNC Turning) is a precision machining process that uses a CNC Turning machine to cut the workpiece in a linear manner while it rotates or “turns” to form a cylindrical part.

Done using machinery lathes, the process essentially trims the diameter of the workpiece to a particular shape as per the given dimensions, resulting in a polished ready-made part.

Interestingly, the traditional process dates back to a remote Egyptian time where the concept of lathes has first supposed to have originated.

Nonetheless, it’s one of the most highly-skilled and intricate ways of creating custom components and is used for all sorts of materials from metals to plastics and glass.

How Does CNC Turning Work?

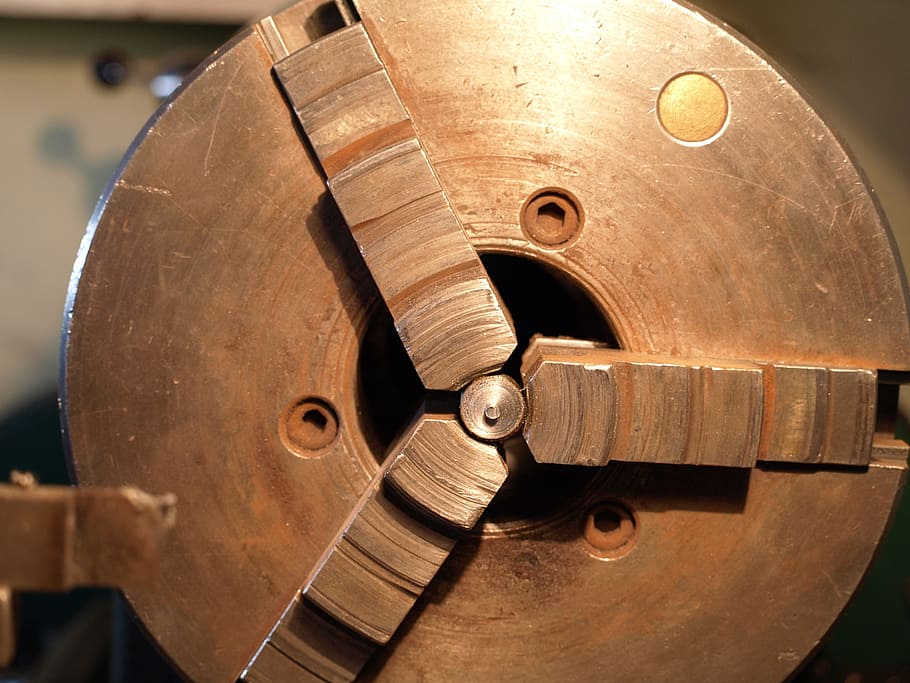

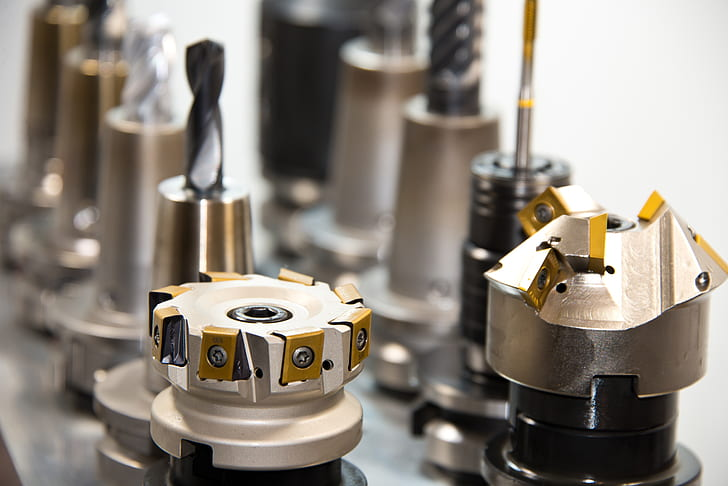

During the CNC turning process, the workpiece (material to be worked on) is established on an instrument called a ‘Chuck’ which is rotated at a specified RPM. During the rotation, sharp CNC turning tools are then moved to the piece to remove excess material and create the needed shape.

As the final piece is created by trimming off the raw material, CNC Turning is also called subtractive machining as opposed to 3D Printing, which is additive. Though the shapes come out to be primarily cylindrical, other shapes such as squares or hexagons can also be created.

The turning process happens in specialized CNC Turning Shops. The lathes used for the process are either horizontal or vertical which depends on the weight and tolerance range of the piece being worked on.

Also, if the CNC Turning Shop providing turning services has access to both turning and milling facilities, the rotation can be opted out for other milling operations.

CNC Turning can be applied to both the exterior as well as the interior of the workpiece (also called ‘boring’) to create more tube-shaped components.

Perfect! Now that you’re cleared with the basics, let’s understand the different types of CNC turning processes.

What are the Types of CNC Turning Operations

There are various turning operations that can be utilized to cut different shapes for a workpiece such as straight, curved, or grooved.

- Tapered Turning

In tapered turning, a canonical surface is created by incremental reductions or an increase in the workpiece’s overall diameter from one part to another.

The tapered elements are prominently used in machine constructions and can be internal or external.

2. Hard Turning

Essentially, Hard Turning is the process of turning a workpiece harder than 45 HRC (Rockwell C). Mainly performed after heat treating the piece, hard turning is generally used as a replacement for grinding operations.

3. Facing

Facing in the context of turning refers to the removal of material by bringing the cutting tool an appropriate angle of the rotating workpiece’s axis to create a flat surface.

A 4-Jaw Chuck can also be used in Facing to create shapes different non-cylindrical shapes.

4. Spherical Turning

In spherical turning, a spherical or ball-shaped surface is created on the workpiece with gradual reductions of the material.

It’s mainly applicable for equipment like gears, injection, and hydraulic components.

5. Boring

Boring is basically the process of widening a drilled hole in a workpiece by subtracting material using a single-point cutting bit.

It’s essentially used to cut holes of accurate dimensions as well as tapered holes in a material such as that of a cylinder or a pipe.

6. Parting

Parting, as the name suggests, deals with removing a part of specific length from the original stock piece by feeding a blade-like cutting tool to it.

7. Grooving

Similar to Parting, Grooving deals with cutting a piece from its original raw material to a specific depth without totally cutting it apart from it.

It can be done on both the internal as well as external areas of the piece.

8. Drilling

Drilling is essentially the process of creating a round hole inside the workpiece to remove material from it.

The drilling operation is done by firmly holding the standard drill press in the turret of the lathe and feeding it directly to the piece.

9. Knurling

Knurling is a special kind of turning process in which a straight line or diamond-shaped pattern is impreses onto the workpiece’s surface to make for a better appearance and gripping surface.

This is done using a unique tool.

Final Thoughts

To conclude, CNC Turning is undoubtedly vast.

But by understanding multiple types of operations and features supported by CNC turning laths, you can get a much better idea of what could work best for your manufacturing requirement.

We hope this post has shed some light on CNC turning as a powerful machining process, which you can think of for your machining needs.

Have a manufacturing requirement that requires CNC turning? Feel free to let us know.

We are a CNC turning shop in Houston, Texas and offer excellent CNC turning services for a wide range of industries. Replete with state-of-the-art CNC turning lathes, we can easily machine your part to perfection.