CNC (Computer Numerical Control) machining is a pre-programmed process of designing, engineering, and manufacturing machine parts using computer technology. Gone are those days where every little step in the designing and manufacturing was handled manually. Today, with the emergence of smart tech, CNC’s have become so powerful that they work efficiently with minor to none human interruption.

Manufacturers and small hub engineers who implement CNC’s and manufacture machine parts for businesses have adopted working with CNC machine shop concept where every kind of engineering work is carried out effectively and efficiently.

In CNC machine shops, the two popular services provided by them are:

- CNC milling services

- CNC turning services

For CNC milling services, there are dedicated CNC milling shops that offer complete milling solutions. Here on the production floor, CNC milling machines are responsible for computerizing the cutting tools. At the same time, cutting tools rotate and cut the material at multi-points to get the custom design of the material.

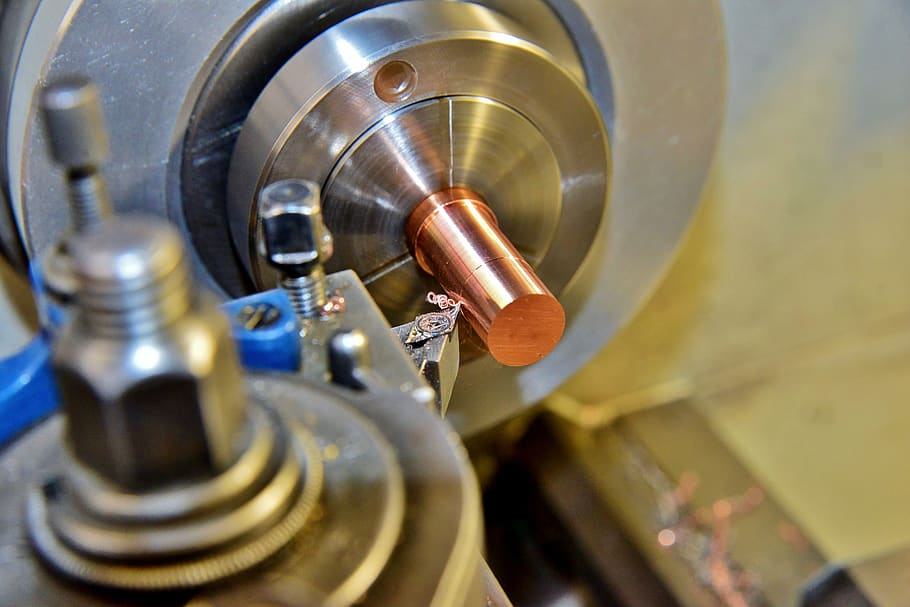

In CNC turning services, CNC turning shops are responsible for the manufacturing process where the workpiece is held in a chuck and rotated. While a tool removes the material to create the custom desired shape.

Over the years, both the process of milling and turning has evolved to new heights, and engineers can now design and manufacture complex designs with the help of such technology. CNC milling services are considered better while manufacturing complex components with precision in high demand.

Here are some advantages of CNC Turning Shops:

Precision Finished Parts and Components:

Over the years, people have approached experienced machinists to manufacture parts in their own way. But since the evolution of CNC’s, the scenario has changed a lot, and machining of complex parts isn’t as challenging as it used to be for engineers.

Thanks to CNC turning shops that experts can now work with advanced technologies and can carry out extreme production operations with complete accuracy. This is why precision of components and parts can be done using CNC turning services.

Since the whole machine is computerized and pre-programmed to work with perfection on a workpiece, which leaves no probability of errors. Thus it means that the last component completed in a production run is the same as the first.

In short, the precision capabilities of any CNC machine shop are essential. If you require tight tolerances for your projects and here high precision machining could save lives in such cases.

Versatility and Flexibility:

Since the significant two aspects of production are designing and manufacturing, manufacturers must need to be versatile with their design and flexible with their approach.

Because today’s modern world is evolving day by day, the machining process that worked today might not work after ten years. This is why CNC machines are designed to be adaptable and approachable.

It’s important to understand that not every industry uses the same materials for their parts, and materials are selected according to their application, especially in CNC milling shops and CNC turning shops.

Since CNC turning services don’t encounter limitations in terms of materials used. It leads to the versatility of the process and makes it easier for engineers to deal with different materials.

Apart from choosing materials, CNC turning shops are known for their brisk and sway approaches for designing and production. Thus now experts can examine errors before any production run and develop alternative and effective ways to do the production. Thus, this flexibility to different approaches makes CNC turning shops unique.

Safety and Faster Results:

We know that terms like ‘safety’ and ‘fastness’ don’t go well in one sentence. But with CNC milling shops and CNC turning shops, high skilled laborers and employees are in charge of the production floor.

These operators on the floor are taken through a safety training program because there’s always a potential risk when you’re dealing with giant machines. Thus to ensure 100% safety, all the operators and engineers follow strict regulations and guidelines while operating.

But since the whole CNC machines can be pre-programmed and instructed via computers, thus there is no need for any physical presence beside them, and engineers are experienced enough to run machines with no errors.

Right now there is barely any other machining process that could be as fast as CNC machining in terms of faster results. Because with CNC turning shops, there is little to no possibility of errors right from the start.

Therefore when we start with prototype designing, the team of experienced engineers will calculate several factors like heat tolerance, stress resistance, hardness, fastening, design tolerance, and materials to come up with a prototype and they will evaluate the whole manufacturing process to make it a success.

Since all the examination is done on computer programs, which leads to less possibility of manual errors if any engineers will assess them in advance to avoid them. Thus once everything is okay, the instructions will be sent to CNC turning machines. From there on, complete production runs at a quicker pace without compromising on the quality of the finished product.

Thus, in the end, the CNC machines help the whole process of designing and manufacturing easier and way faster.

Conclusion:

CNC turning shops are exceptionally great for any engineering purposes. There is no doubt that they yield more growth than any other machining process because every step of the process, from the initial plans to material selection to production, happens at the exact location. Hence industries do rely on and trust CNC turning services for better and faster manufacturing.