Did you know that today’s industrial manufacturing environment is called industry 4.0? This means we are in the 4th industrial revolution. Manufacturers are using the best of every aspect of engineering and Information Technology (IT) to maximize production, manage production efficiency, and reduce wastage and turn-around time.

As we are almost halfway through 2019, manufacturing trends have changed over the years which is what you should be aware of. By following the latest trends you can literally outperform your competitors and maximize success.

To make sure you don’t miss out on any, we’ve curated some of the latest and greatest manufacturing trends for you to follow.

Here they are:

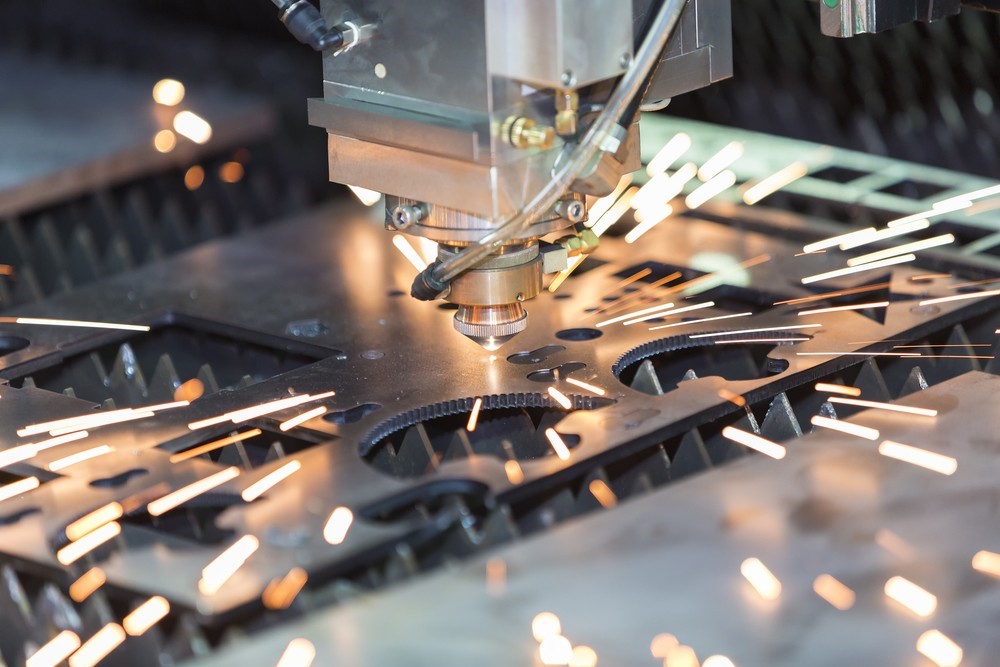

1: CNC machining will become more relevant than ever.

Nowadays, every industrial manufacturing company focuses more on production efficiency with minimum errors. Industries keep on developing new methods to minimize human errors and maximize the utilization of raw materials to create quality products.

CNC machining is by far the most cost-effective and efficient manufacturing method for most companies and industries like automobiles, medical, and aerospace. They will require CNC machining the most due to its ability to produce huge scale products with great accuracy.

As far as other industries are concerned, CNC machining will remain an integral part of manufacturing for bulk manufacturing, prototyping, rapid manufacturing of nuts, bolts, cogs, etc. Thereby assisting companies to streamline the production process with other manufacturing tools like robotics and 3D printers.

The main objective of CNC machining is to reduce errors by processing the computerized data and producing the finalized product repeatedly without losing accuracy. That’s why it will remain a go-to auto manufacturing process for many industries in the coming years.

What will be new is the introduction of solar-powered CNC machines due to the adoption of a more environment-friendly trend in the manufacturing sector. Also, some CNC machines will be used in generating electricity.

2: IoT is the Next Big Thing

Speaking of transformations in the manufacturing industry, IoT (Internet of Things) is the next big thing that will make manufacturing even more efficient.

Although IoT has been prominent in the manufacturing industry for the past few years, many industries are rapidly leveraging IoT to further optimize the manufacturing process.

Key benefits of IoT manufacturing are as follow:

- Increased efficiency

- Quick product innovation

- Improved safety by decreasing human involvement

- Wireless access and operation

Due to faster internet and improved cloud computing, it is possible for manufacturers to reduce human interference and remotely access the machines with the same accuracy.

All these factors make IoT the next big thing to look out for in manufacturing.

3: 3D printers and rapid prototyping

As you already know, time is the most crucial factor in manufacturing. In today’s competitive environment, any time advantage you have over your competitors can make a difference when it comes to winning and losing the market share.

That’s why rapid prototyping has been the most common approach for product prototyping in many industries. It refers to creating multiple scale models of your product to experiment and refine a new product idea to perfection. It is a much faster and cheaper alternative to speeding up your manufacturing process.

Use of 3D printers in the industry is said to increase in the near future, not only for prototyping but also to create products themselves. Products like customizable dolls, artifacts, jewelry, etc. can be produced directly using 3D printers.

3D printing is also used in medical industries to create a replica of implants, dentures, etc. to help patients. The real estate industry also uses 3D printing to create a small scale replica of buildings to showcase intricate details of the outside area, gardens, and other amenities.

Additive technologies like 3D printing have revolutionized rapid prototyping and it will keep on improving as time passes by.

For instance: 3D printers of the future could process any synthetic material to create a 3D replica so that you can create an almost-exact product with the same raw materials and intricate details. Also, the use of 3D printers and rapid prototyping is said to expand to other industries like education, pharma, etc.

4: Finding a tech-savvy workforce will be tough

As integrating latest technologies have become mandatory for all businesses to stay ahead of the curve, companies need to have a tech-savvy workforce to operate these technologies with finesse.

However, most industries today are struggling to find employees that are well-versed with these latest technologies. This talent gap in the industry is limiting their potential as they are forced to stick to old-school manufacturing technologies.

To fill up this gap, companies either train their current employees to keep themselves updated or make their business appear more appealing to tech-savvy employees by partnering with reputed institutes.

The best way to have specialized manufacturing services is to hire a third-party manufacturing workshop. It is much cost-effective way to get robust manufacturing expertise and services and it also saves you from the hassle of purchasing huge machines as well.

What’s more, these machine workshops are always ahead of top manufacturing trends, well-equipped with the latest machinery, and boast an expert staff to fine-tune your manufacturing efforts and increase production.

5: VR and AR will simplify the manufacturing process.

Speaking of the latest technologies used in manufacturing, virtual reality (VR) and augmented reality (AR) will be more prominent than ever in the near future.

Virtual reality can work in harmony with CAD to help designers better visualize the product and make improvements. As of now, the integration of VR and AR in manufacturing is getting much more accessible to SMEs. These technologies will greatly benefit companies to create beautiful and highly functional products that satisfy consumer needs.

Final Thoughts

To sum it all up, the manufacturing industry is one of the most dynamic industries in the world. 2019 is said to bring tons of technological advancements in the manufacturing sector to help create quality products for customers.

These 5 trends are the game changers in manufacturing 4.0 and adopting them will help you make rapid advancements in manufacturing.

You should also keep in mind that prototyping and design machining services will become even more prominent for manufacturing industries to save cost and get the right expertise.

Speaking of which, if you are looking for top-notch manufacturing expertise in one place, then we, as a leading CNC machining company, can help you out. We own a dedicated CNC machining workshop in Houston, Texas and provide value-for-money CNC machining service to local businesses.

Just send us your queries and we’ll look into your manufacturing requirements.