Let’s face it.

No matter what industry you’re from, safe and accurate manufacturing is always a high priority. With the market becoming more competitive than ever due to the rising costs of materials or fluctuating economy, businesses find it hard to make profits.

But that’s not the case with precision machining.

A precision machine shop gives you the facility and services to produce high-quality manufacturing parts your customers can rely on in this competitive world.

If you’re still thinking whether partnering with a high precision machine shop is ideal for your business or not, read along.

Here are 5 ways precision CNC machining services can value to your business:

Manufacture Error-free Accurate Parts

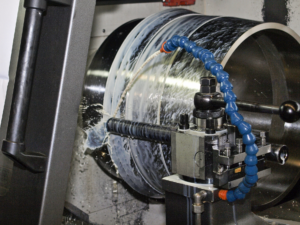

Compared to other manufacturing techniques, precision machining utilizes high-speed lathes that provide consistent accuracy for your parts.

Precision machine shops use equipment that intakes CAD-based blueprints to interpret design instructions and then perform the operation. This lets them perform machining tasks with high accuracy and with varied multi-axis positioning.

Most importantly, CNC machines let you repeat the same operation for more accuracy of your part in a consistent and timely manner.

As these machines are specially engineered, they beat any human when it comes to speed, accuracy, and reliability.

In this way, precision CNC machines shops give you error-free machined parts in less time without sacrificing quality.

Prevents Scrap Wastage

Plenty of times manual machining results in excessive scrap wastage. As materials come at a cost, this impacts profitability.

Add that with labor costs for inspecting and sorting which doubles your expenses.

Precision machine shops, on the other hand, have access to CNC technology that optimally manufactures parts with little-to-no wastage.

Thanks to the robust capabilities of CAD/CAM software, CNC machine shops can perfectly visualize the design and identity optimum processes prior to turning or drilling the material.

This lets you reduce internal scrap wastage to a great extent.

Help You Save Cost

The greatest benefit of partnering with a precision machine shop is it helps you save plenty of costs.

Thanks to the comprehensive nature of CNC machining, parts can be produced with minimal wastage, minimum labor, and almost zero error possibilities.

What’s more, as most precision machine shops have their own material inventories, they can also help you save the money spent on raw material and supply chain management.

Thus compared to doing it in-house, CNC machine shops can save costs both in terms of materials and employee wages as well as bring better ROI in the long run.

Have Immense Professional Expertise

Being a dedicated place for precision manufacturing, CNC machine shops have a workforce of skilled machinists, engineers, and designers who are highly trained in the craft of machining.

Together they bring years of technical expertise which help them understand your requirements and manufacture parts quickly yet professionally.

They are also highly skilled in working with specialized tools that cannot be easily operated by a novice.

Such machining experts also assist you during each phase of your manufacturing journey so get a better picture of the process.

Access to Emergency Machining Services

In certain scenarios, businesses are faced with emergency situations in which manufacturing demands have to be met under tight deadlines.

For such cases, precision machine shops offer dedicated emergency machining services to help businesses during a breakdown.

With the expertise of professional machinists available at any given time, businesses can save themselves from having to deal with emergency manufacturing situations.

Machine a Wide Range of Materials

While many businesses turn to 3D Printing or other techniques for manufacturing, they offer quite limited options when it comes to materials.

3D Printers, while offering different material filaments, still fall short when it comes to a certain set of metals used in specialized industries.

Precision machines can work with any type of materials from metals like titanium, alloy, aluminum to plastic, wood, foam, and more to create accurate parts.

This gives you an edge when manufacturing your parts. By outsourcing your needs to a precision machine shop, you can machine almost any material to a particular shape and in the right quantity.

Deliver Parts in Quick Turnaround Time

When it comes to the present-day modern industry, time is money.

In short, you simply cannot compete in the market if you are not able to produce and deliver parts in a timely manner.

This is where precision machine shops come in handy.

Their highly-efficient machines take care of everything from start to finish and deliver parts in short turnaround times.

By adequately utilizing the needed resources, CNC machine shops improve throughput with continual operations without breaks. This significantly enhances the delivery time for your parts while keeping the overall production costs low.

Thanks to this CNC machine shops also offer competitive pricing for your parts.

Final Thoughts

As you may have guessed by now, there are plenty of ways precision machine shops can help you manufacture your part.

By partnering with a CNC machine shop you can accurately manufacture any type of part with tight tolerances and also save yourself the hassle of unnecessary costs and meeting deadlines.

Are you on the lookout for one yourself? If yes, you don’t have to look elsewhere.

We are a precision machine shop ourselves based in Houston, Texas who offer a wide variety of CNC machining services in the realm of manufacturing, custom machining, and metal fabrication.

Let us know your machining requirements, and we’ll take it from there.