In today’s world of sci-fi and technological revolution, let’s not forget we’ve come a long way in terms of CNC machining capabilities.

Of course! At the heart of it all we’re talking about the lathe machine, a device that works on your materials from start to finish and brings you the desired finished precision machined components.

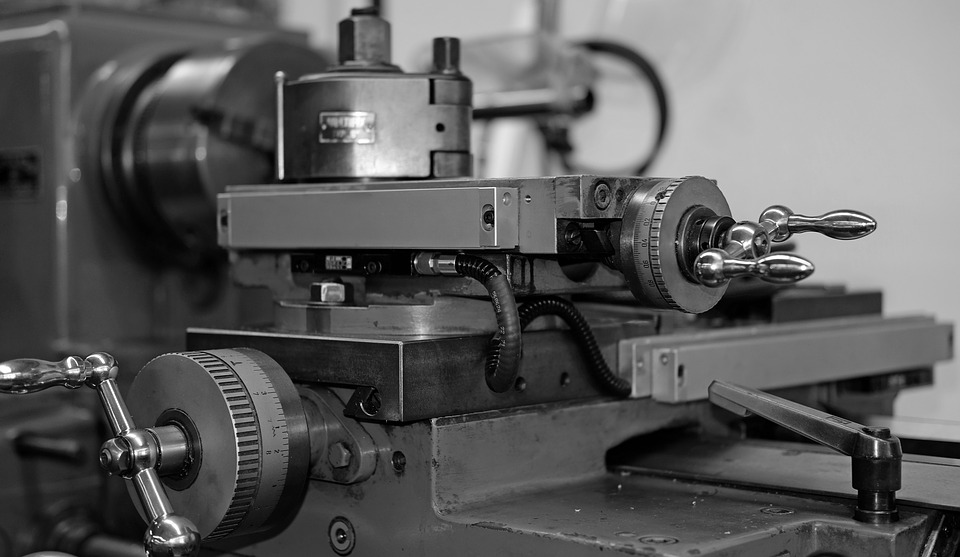

While in the past, manual machining lathes required intense labor and time to create quality parts, today the same can be achieved with advanced CNC lathes to provide custom CNC machining services.

Becoming the norm as go-to manufacturing tools, these lathes have replaced their old traditional counterparts and are used by all kind of industries for their manufacturing needs.

Which makes understanding them even important.

If you are on the lookout for CNC lathe or CNC machining services, understanding more about lathe machines, known as well as turning machines, can help you pick the ideal CNC service provider to accomplish your needs.

Let’s dive deeper and understand what CNC turning machines are all about.

What is a CNC Turning Machine?

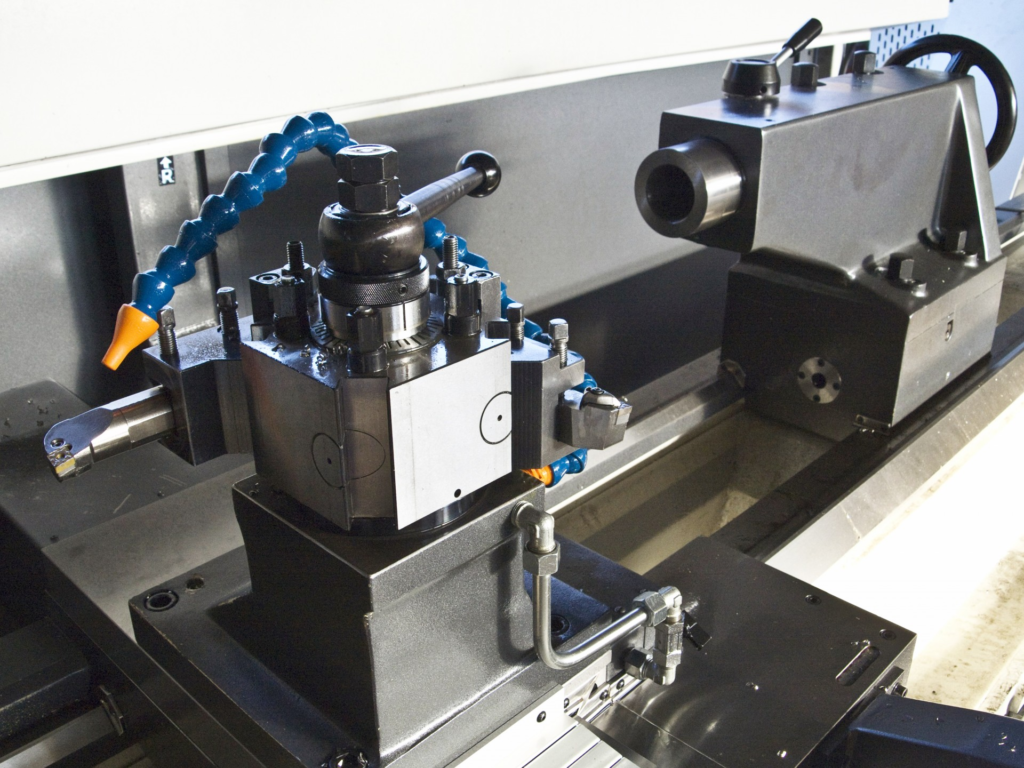

Simply put, a CNC Turning machine is a reinvented manual lathe that utilizes computer controls to rotate a workpiece and cut off excess materials using sharp cutting tools and drill bits to create symmetrical parts.

The cnc turning machines spin the workpiece along a single vertical or horizontal axis while feeding it the cutting tool to create a particular shape.

As opposed to traditional lathe machines, CNC turning machines are programmed by machinists to perform detailed operations such as cuts, metal spinning, metalworking, thermal spraying, etc.

Different Types of Turning Machines

CNC turning machines can be categorized into two different types namely Vertical Lathes and Horizontal Lathes.

1. Vertical CNC Lathes

Vertical cnc Turning Lathe, or machine centers, as the name suggests, have their spindle axis oriented in a vertical fashion where the spindle holds the milling cutters. The workpiece is then rotated upright which lets the spindle cut at certain angles.

Compared to horizontal cnc turning lathes, the vertical lathes generally occupy a small space. These machines are also great for manufacturing workpieces that are large and heavy in nature.

The vertical design also helps the machine stay stable throughout the process which results in more accurately cut parts.

Due to such capabilities, CNC vertical lathes, known as well as CNC Vertical Turning machines, considerably more expensive than their horizontal counterparts.

2. Horizontal CNC Lathes

Horizontal CNC lathes, have the configuration of their cutters mounted horizontally. The workpiece on these machines rotate cylindrically while the tools cut the extra materials.

As the workpiece is held on the chuck vertically, the machines are ideal for working on lighter materials or metals.

Horizontal CNC Turning Machines generally take up more space since they require the workpieces to lie vertically. This also makes them ideal for producing small to mid-sized pieces which may also include shaping flat surfaces.

Now that we’ve distinguished the two major categories, here are some of the most popular turning machines in use today you must know:

Engine Lathes

Engine lathes are some of the most popular and versatile CNC machines in use today that are used for CNC Turning machining. They can operate on a varying range of speeds and are mostly used for low-power and high-power tasks. Generally the first choice among those who need to work on multiple metals.

Speed Lathes

These turning machines do at most two operations but at high speeds. It is much simpler than other lathe machines and used for light work. This also makes it less versatile than the rest.

Turret Lathes

These turning machines have a tool holder to help perform multiple operations on a singular workpiece. These multitasking capabilities make them ideal for quick and sequential tasks.

Gap Bed Lathes

Gap Bed Lathes are those machines in which the bed section can be detached to adjust large diameter and often longer workpieces. When operating these lathe turning machines, operators have the ability to distance the bed from the headstock by about two feet.

Why Choose CNC Lathes Over Manual Lathes?

Great! Now that you know about different lathe/Turning machines, let’s find out why you should prefer CNC Turning, or Lathes, over more traditional ones.

1. Work is Entirely Automated, Easy & Fast

Compared to manual lathe machines, CNC turning machines can produce tons of parts of similar dimensions at the click of a button, while maintaining a precision cnc turning services with awesome quality. Work can thus be made simple and easy on CNC machines, which is a great relief to all the CNC Machine Shops.

No matter what your requirements, they allow you to produce parts of tight tolerances and complex geometries at a non-stop pace.

2. They Are More Flexible and Versatile

What makes CNC turning machines so great for production is their versatility. Unlike manual turning, or lathe, they can work on multiple types of workpieces and create almost any shape which is humanly impossible.

3. Eliminates Human Errors Completely

A major concern in terms of part production and manufacturing is inaccuracy and errors. Thanks to precision CNC machining technology, accuracy is taken care of from the get-go in CNC lathe machines making along with CNC Milling Machines, them ideal for industries requiring high precision machined parts.

4. They Save You a Lot of Money

CNC turning machines offer tremendous benefits in terms of cost savings.

Instead of having someone manually churn out the parts for you, precision machine shops, such as ER Machining, equipped with super awesome precision CNC turning machines that turn raw into your per drawing’s made cnc machined parts. Those advanced Turning machines help you save you costs in terms of setup, material waste, and most importantly, labor costs.

Final Thoughts

As you can see, CNC turning machines are miles ahead in terms of accuracy, usage, as well as offer plenty of advantages over traditional turning machines or lathes.

So now that you have all the needed information about CNC lathes, it’ll help you pick the best CNC machining provider the next time you have machining requirements. You are welcome to reach out to ER Machining and we will treat you as part of the family. ER Machining is a CNC precision machine shop based in Houston, Texas that offers excellent CNC milling services and CNC turning services for major industries such as

the aerospace industries, oil & gas industries, energy industries and more…. With our top of the line precision CNC turning machines and precision cnc milling machines, we can help you with any type of machining requirement.