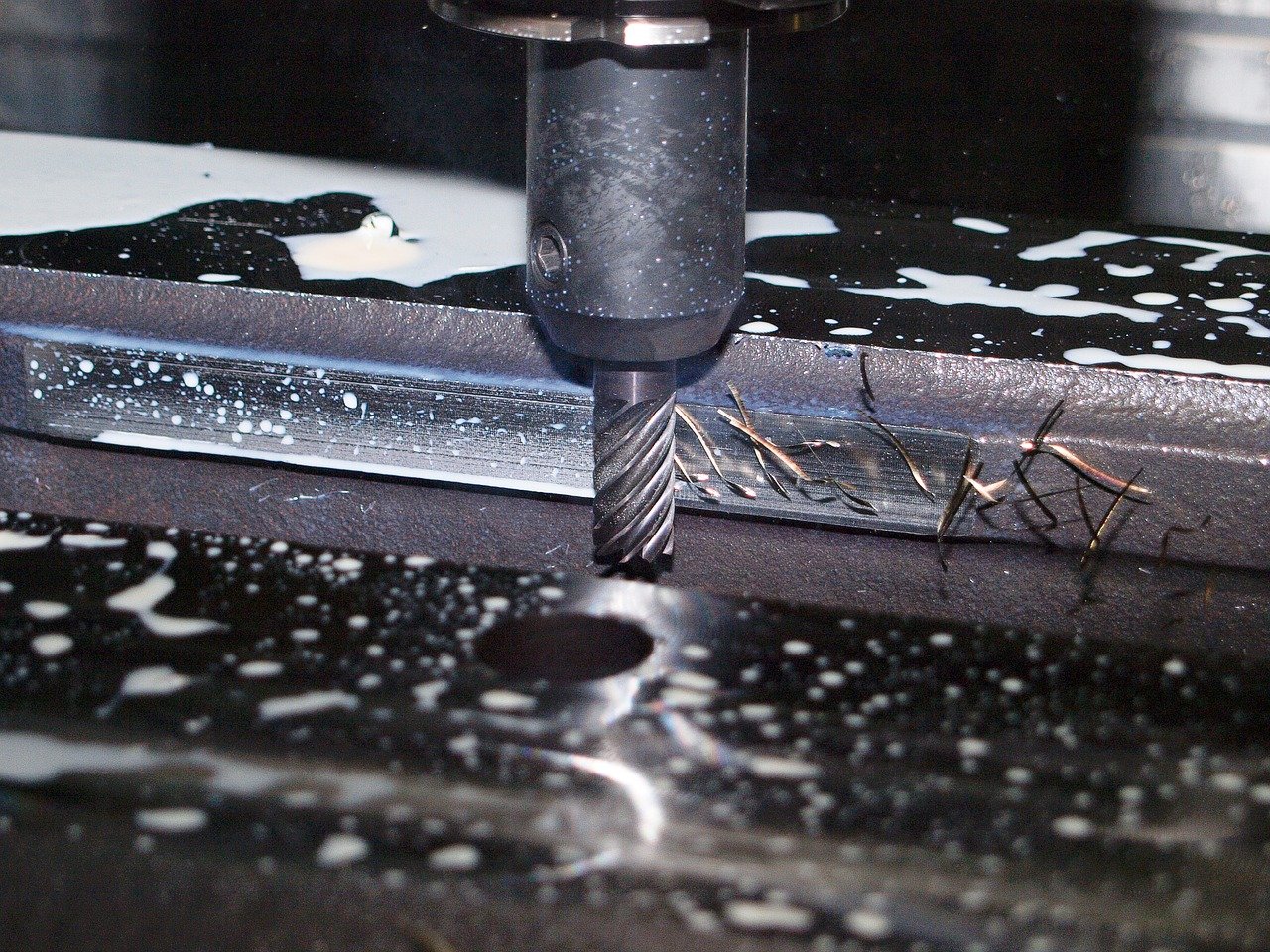

CNC Milling is a popular and effective way to produce your designed product. The machines use rotary cutters to bring your design out of a workpiece accurately. It is a very popular way to process designs that are impossible to do in hand and other methods.

However, not all types of materials cannot be processed in CNC milling. There are a few factors you must consider before choosing the materials you want to use in your products for CNC milling.

What is CNC Milling?

CNC stands for computer numerical control. A 3D model of your design is processed in the computer. The computer uses a robotic hand with various types of rotary cutters. The workpiece is placed on a table that can also move in different axes to accompany the milling process. With the accuracy and efficiency of CNC milling. CNC milling shops in Texas can easily produce products and showpieces with complex designs and structures.

Apart from CNC milling, we have CNC turning technology. CNC turning service is used for structure with cylindrical and symmetric shape. In CNC turning, the blades do not rotate; rather, the workpiece rotates at great speed with the attached platform. The traditional baseball bats are produced in CNC turning shops with CNC turning technology.

Materials to use for CNC Milling

There is a wide range of material selection for CNC milling. You can use metals, plastic, wood, and foam. The most used materials are metal.

Factors to Consider before Selecting a Metal

Before choosing a metal to use in a CNC milling shop, you should consider the following 4 factors of CNC milling services. These are the basic factors for every material for CNC milling.

- Tensile Strength

It indicates how much resistance an object produces before falling apart under tension. If your product has to deal with high pulling pressure, then you should consider choosing a metal with high tensile strength.

- Hardness

Hardness refers to how well an object can hold its shape and structure after processing. If you are designing a product that has a richly detailed design, then choose the metal that has the highest hardness score. Hardness is computed with Rockwell or Brinell hardness number.

- Resistance for Friction

CNC milling machine works with rotary cutters that remove metals with friction and shape it. So, the lower the friction resistance, the lower the cost and energy required for producing that material. If your choice of metal or material has a high threshold for friction or self-lubricating properties, then it will be very difficult to give it your desire shape.

- Stress Capacity

Stress capacity gives you an idea about how much stress the metal can handle. It also indicates how well your product can handle and maintain itself in heat. If you are making gear parts and other equipment that have to deal with intense friction, then choose a metal with high-stress capacity. Stainless steel and Titanium are a great choice in this case.

Metals that have Great CNC Milling Capabilities:

- Aluminum

Aluminum is easy to process using CNC machining services. It is quicker to cut and shape. As a result, it is the best choice for CNC milling. Statistically, aluminum is the most used material for CNC milling, and its cost-effectiveness, time efficiency makes it a great economical choice.

Moreover, aluminum forms a protective layer, which makes it last longer than other materials. The extra strength and corrosion resistance make it a perfect candidate for medical gear, electronic parts, aircraft parts, etc.

- Steel

Steel is best suited for making products that have to deal with high pressure and stress. The stability and resistance make it handle stronger wields. As a result, steel is used for making gears, shaft parts, and other similar equipment for machines. The alloy of the steel differs for different types of products

- Stainless steel

Stainless steel is a great and far better choice than using steel and aluminum. It is corrosion-proof and can handle the heat. As a result, it has many possibilities for CNC milling. NASA and other aerospace industries use stainless steel for making rocket and space shuttle parts. Its purity level makes it perfect for surgical equipment, and high conductivity allows it to be used for electronic parts. So basically, you can use stainless steel 8n CNC milling to produce any kind of product you want.

- Titanium

Titanium is a viable choice for making industry grade product and also for making equipment and parts for industry use. Its high-temperature threshold and corrosion resistance allow it to be used for long term industry use. Moreover, it is totally environmentally proof. Lightweight yet strong makes it a good choice for medical implants, aerospace, aircraft, and even jewelry.

- Brass

If you are looking for stability at a low price, then brass is the best option. It is famous for its cost-efficiency. As it has low friction capacity and high corrosion resistance, you can make low-cost products for long term use.

- Other Metals

Alongside these 5 metals, there are more usable metals such as Bronze, Zinc, Copper, Magnesium. Some of them offer great stability and other conductivity.

Conclusion:

Because of high stability, resistance, and other properties, anyone can think that they should use metals for every product. Visit the machine shop in Houston, Texas for your CNC Projects.